Reel-to-Reel Electroplating in Custom Connector Manufacturing: How It Creates High-Performance Components

Your Reel-To-Reel Stamping Experts

We don’t just stamp – we design, plate, assemble and more, creating a simplified process to meet your demanding production needs.

The Revolution of Reel-to-Reel Electroplating

The electroplating technique of reel-to-reel is more than a simple plating method. Today, it functions as a strategic approach which supports the manufacture of highly complex electrical and electronic applications. The process merges rapid production with the highest quality to deliver high-performance components for a wide range of industrial sectors.

Understanding the Process

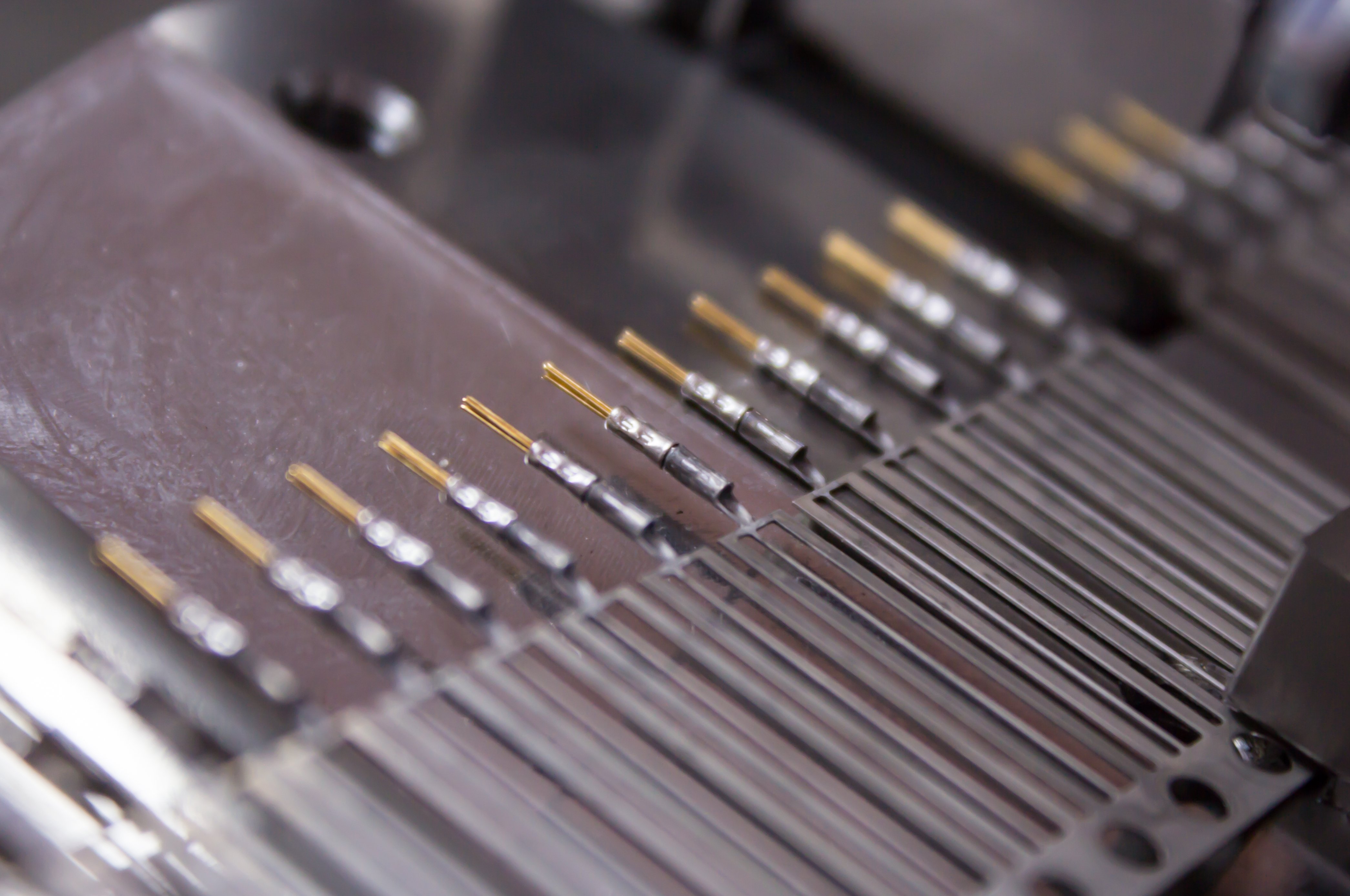

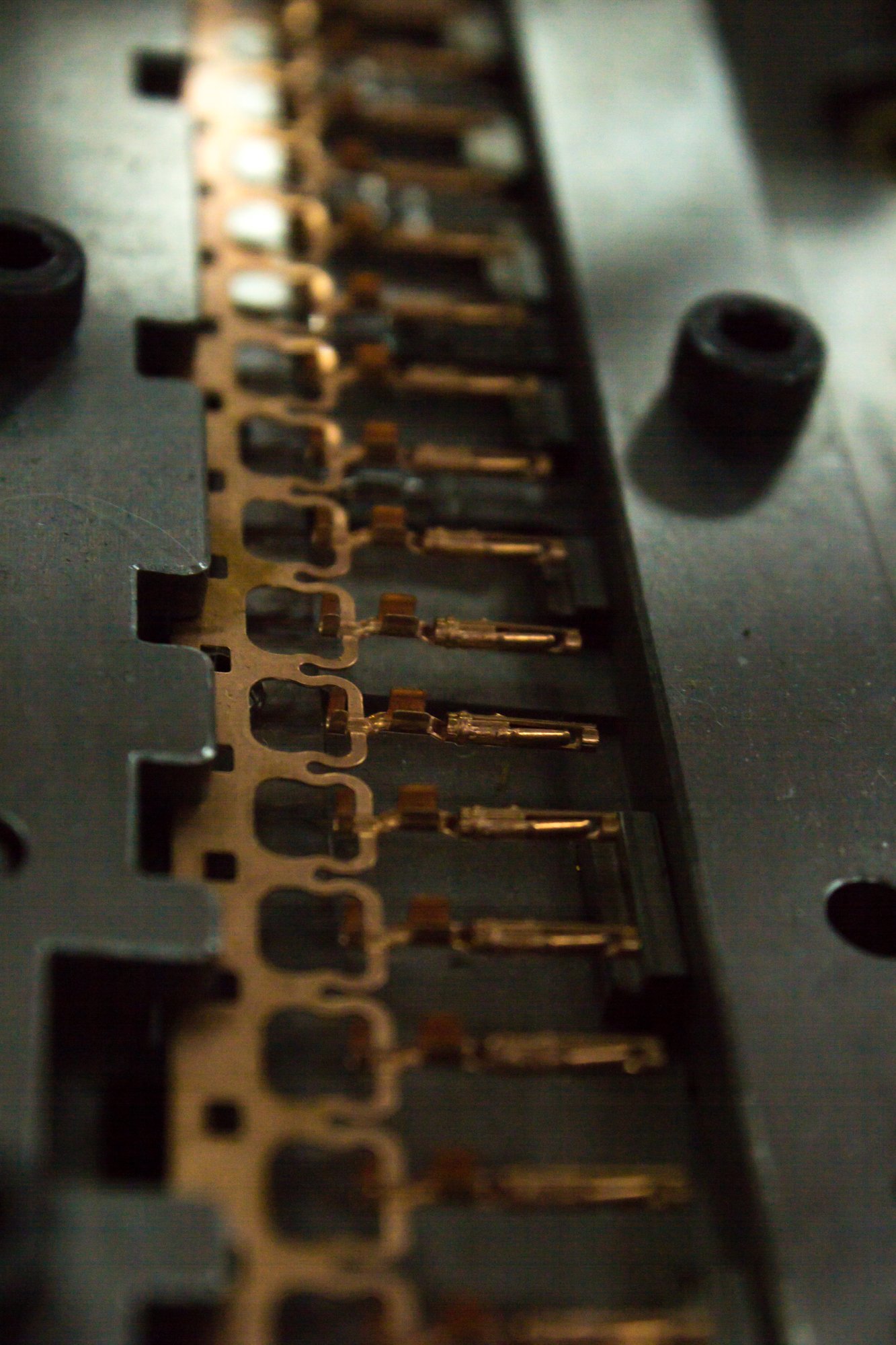

Electroplating when combined with reel-to-reel technology continuously applies metal coatings to stamped metal components on a moving carrier strip. The strip is delivered from a coil before it passes through electroplating baths before rewinding back into a coil. This automated linear process gets rid of batch processing problems while enabling complete control of deposit thickness and coverage and adhesion quality.

The continuous operation of each plated part moves through the system quickly under controlled tension and precise bath chemistry to maintain uniform results. The entire strip moves as one unit during this process which makes it most effective for manufacturing large quantities of miniature precision-critical components such as those found in automotive and medical and telecommunications applications.

From Stamping to Plating – A Connected Approach

Leading manufacturers succeed through their capability to integrate plating operations within their tightly controlled production lines.

Batten & Allen's Cirencester facility enables reel-to-reel electroplating and stamping all under one roof. This connection between core operations provides process control levels that become challenging to maintain when operations are carried out at separate locations. Having stamping and plating functions in one location creates shorter production cycles while maintaining the highest levels of quality.

Customers experience faster delivery together with enhanced design options and robust, dependable component performance.

Why It Matters in Connector Manufacturing

Custom connectors need to undergo multiple mating operations and tough environmental conditions as well as different current loads while keeping their resistance low and their structural integrity intact. The metal coatings on connector contacts determine how well the connector performs during product operation.

The precise application of metal finishes becomes possible through reel-to-reel electroplating while maintaining repeatable scalability that supports high-specification connector requirements.

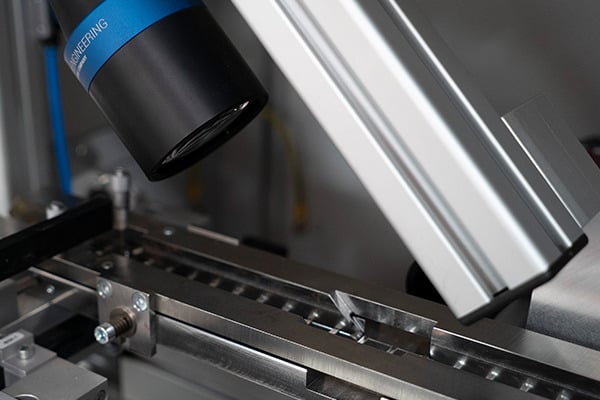

The inherent uniformity of reel-to-reel electroplating operations offers immediate wins. Reliability of assembly increases when components automatically maintain precise dimensions and strict finishing standards. Quality inspection systems that use in-line vision cameras enable real-time verification of plating integrity which, in turn, minimises defects.

Setting the Standard for Scalable Precision

The development of reel-to-reel electroplating technology has helped to create new possibilities in producing high-performance connectors. Batten & Allen use this technology to produce millions of plated parts daily with no impact on tolerances or material performance. The advance in technology means today’s reel-to-reel capability now serves as an operational norm within precision manufacturing.

The Engineering Behind the Process: Precision Meets Scale

The combination of technical advancement and digital monitoring technologies means electroplating reel-to-reel systems can process millions of small, high precision components daily. The plating operation consists of a precisely engineered process which requires exact management of strip tension along with plating current to fulfil connector manufacturing requirements.

Maintaining Tension and Alignment

The process starts with keeping constant tension across the entire carrier strip length. Capstan systems maintain a steady controlled feed of the strip as it continuously moves from the unwinding coil through the plating cells before rewinding ready for the next stage.

The plating process requires the coil to be kept under consistent tension and alignment throughout to prevent defects and component misalignment. Systems preserve stamped forms while maintaining perfect strip tension to allow contact areas to pass through the plating baths at exactly the right speeds.

-1.jpg?width=2000&name=BAJun24Manu%20(72)-1.jpg)

Controlled Plating Environments

The plating process depends almost wholly on the modular cell system. Each cell contains carefully formulated electrolytic baths, where metal ions are deposited onto the surface of the moving strip. The system features modular design that allows users to apply different finishing configurations, thickness levels and application zones which include full surface, banded and selective plating options.

The electrolyte chemistry is monitored continuously as are plating parameters such as bath temperature, current density and flow rate. Constant agitation and flow distribution inside each tank prevents hotspots and stagnant zones which results in a predictable plating outcome across all parts.

Automation and In-Line Control Systems

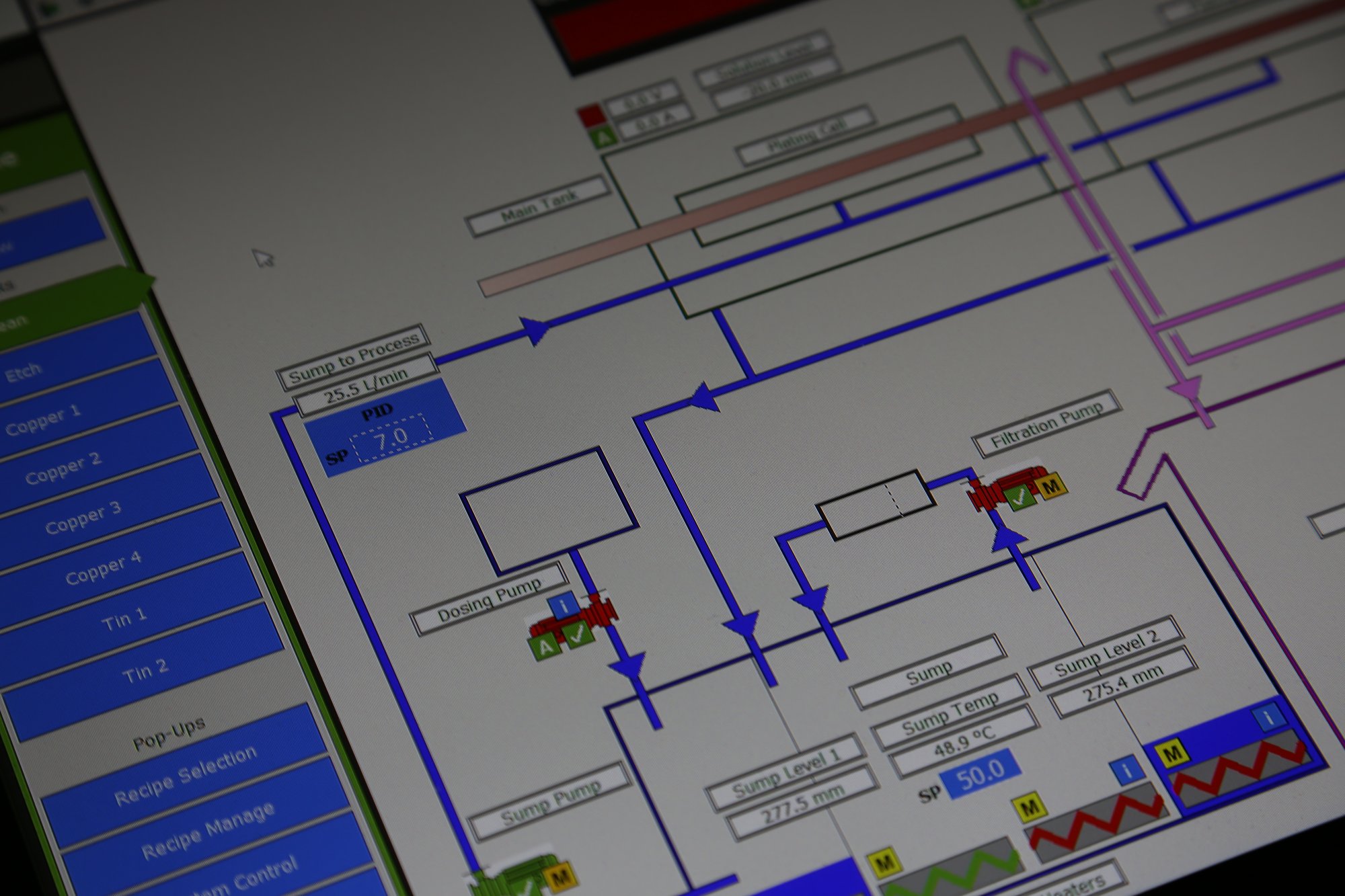

The connector supply chain delivers high production volume which is helped by the complete automation of the process under SCADA (Supervisory Control and Data Acquisition) system management. Operators can monitor all production elements in real time enabling them to handle operations from any location and monitor essential performance metrics and respond immediately to specification deviations.

The plating line includes integrated in-line inspection technologies which work as part of the manufacturing process. The moving strip undergoes inspection through optical cameras and sensors that detect plating defects and surface irregularities and coverage irregularities. These inspection systems decrease human intervention during quality checks and provide immediate, accurate results to maintain uniformity across all manufactured components.

Delivering Volume Without Compromising Quality

The connector supply chain delivers high production volume which is helped by the complete automation of the process under SCADA (Supervisory Control and Data Acquisition) system management. Operators can monitor all production elements in real time enabling them to handle operations from any location and monitor essential performance metrics and respond immediately to specification deviations.

The plating line includes integrated in-line inspection technologies which work as part of the manufacturing process. The moving strip undergoes inspection through optical cameras and sensors that detect plating defects and surface irregularities and coverage irregularities. These inspection systems decrease human intervention during quality checks and provide immediate, accurate results to maintain uniformity across all manufactured components.

Selective and Multi‑Finish Plating: Optimising Material, Cost and Performance

In the manufacture of high-performance custom connectors, the value of a plated finish lies not only in its appearance but in the precise functionality it delivers. With reel-to-reel electroplating, that functionality can be applied exactly where it’s needed, and nowhere else.

Precision Where It Matters Most

Selective plating is a process in which selected zones on the metal strip are plated with a different finish. This is achieved through banding, spot-plating or controlled-depth techniques. In connector manufacturing, this means applying high-conductivity or corrosion-resistant metals such as gold or palladium only to the contact surfaces—where reliable electrical transmission is critical—while the remainder of the component can be finished in a more cost-effective material such as tin or nickel.

This precision avoids unnecessary material usage, allowing premium finishes to be used sparingly without compromising performance. By ensuring that only the functional areas receive precious metal plating, manufacturers can control cost without sacrificing reliability. In an industry where micron-level variations can impact current flow, thermal behaviour or mechanical retention, such accuracy is not just beneficial, it’s essential.

Selective and Multi Finish Plating: Optimising Material, Cost and Performance

The appearance value of plated finishes in high-performance custom connectors depends on their precise functionality, which determines their effectiveness.

The precise application of functionality through reel-to-reel electroplating occurs exactly at the required locations. The manufacturing process benefits from selective plating and multi-finish capabilities because these technologies enable manufacturers to enhance connector performance and conserve valuable materials that ensure sustainable practices.

Precise Selective Plating: Premium Finishes Without The Waste

Selective plating operates through finishing different zones on metal strips by applying banding and spot-plating or controlled-depth techniques.

Connector manufacturers apply high-conductivity metals like gold or palladium specifically to contact surfaces because reliable electrical transmission demands it. It makes perfect sense to finish the rest of the component with less expensive materials like tin or nickel.

This method reduces waste as premium finishes remain limited to the most critical areas of contact.

Manufacturers use precise precious metal plating of functional areas to achieve cost control while maintaining reliability. The industry depends on micron-level precision because it determines current flow and thermal behaviour and mechanical retention in its operations.

The engineering capabilities of multi-finish capability bring flexibility to the process. The current design of modern reel-to-reel electroplating lines includes modular features which enable processing various finishes through a single unified manufacturing process.

The flexibility of the manufacturing process proves essential when working with different customer requirements and application specifications.

The selection of connector finishes depends on its intended use because they can include tin for solderability and nickel for diffusion barriers, as well as copper for conductivity and specialised options like nickel phosphorus for wear resistance.

The mission-critical applications mainly use palladium and gold because these metals excel in environments with high vibration, together with humidity and temperature variations.

Their resistance to oxidation and stable electrical performance make them the material of choice in aerospace, automotive and telecommunications sectors. The ability to selectively plate these metals with other finishes provides manufacturers with market leadership through both performance excellence and procurement advantages.

A Win for the Customer and the Planet

The combination of selective and multi-finish plating in reel-to-reel manufacturing helps companies achieve both sustainability goals and financial gains. The technology supports an efficient method that avoids covering the entire surface with precious metals. This approach achieves two benefits: it reduces both the quantity of metal required and the number of secondary finishing procedures needed.

The plating system operates with precise control between each finish transition which produces sharp boundaries along with clean deposition profiles.

Advanced flow systems together with plating bath management and in-line monitoring work to reduce waste production during high-speed manufacturing operations. The combination of SCADA-controlled systems with advanced flow systems enables rapid parameter adjustments between jobs which maintains process adaptability without affecting production rates.

The design of connectors receives support through new functional possibilities. Modern engineers and designers like Batten & Allen use the latest tech to specify different finishes on one tiny component. A single stamped part often needs multiple contact types together with different resistance levels and various bonding behaviours distributed across its profile. Selective and multi-finish plating enables manufacturers to fulfil these requirements in just one processing step without compromising either consistency, control or budget.

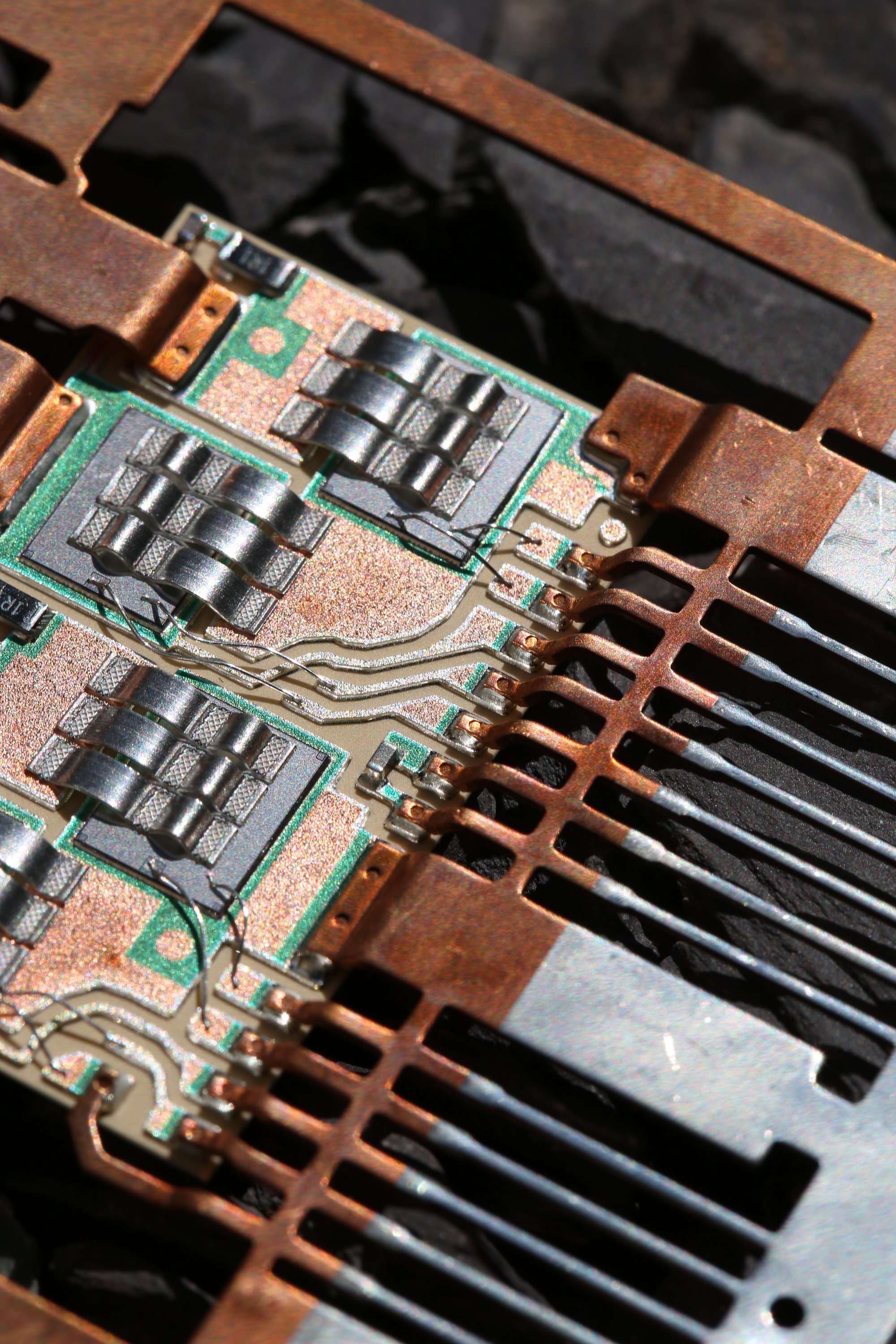

Material Science: Metals, Durability and Electrical Integrity

Reel-to-reel electroplating operates based on scientific principles that evaluate electrical characteristics alongside mechanical properties and long-term durability of metals. Through an understanding of metal behaviours under different stresses engineers design customised solutions which fulfil both technical requirements and commercial needs of present-day connector manufacturing.

Conductivity and Efficiency

Any successful electrical connector needs to transmit current through its structure while keeping resistance levels low.

Copper is a great primary material because of its excellent conductivity and multiple applications. Manufacturers often protect copper from corrosion through over-plated finishes to achieve longer operational life and cost reduction.

Alternatively, some applications use silver as it also provides exceptional electrical conductivity. The chemical reaction of silver prevents its use in humid or sulphuric environments until another sealing or protective layer application is applied.

Protecting Performance in Harsh Environments

Noble metals serve as a great solution for applications requiring resistance against heat along with vibration and corrosion. Palladium and gold demonstrate superior resistance against mechanical and thermal stress.

Gold maintains its inert properties which prevents oxidation, thus maintaining consistent contact resistance throughout its operational lifespan. The ideal material choice for repeated mating surfaces operates in critical sectors such as aerospace, defence and telecommunications.

Palladium provides similar advantages to gold at reduced expense. Meanwhile, a combination of palladium and nickel creates strong protective barrier systems which safeguard base metals while maintaining great operational stability.

Innovative Alloys and Advanced Finishes

Material science advances through continuous manufacturing strategy changes, all of which drive the need for cost-effective alternatives that minimise precious metal consumption.

The development of clad systems and alloyed finishes represents advanced materials that merge different metals to deliver necessary functionalities using reduced material amounts. The combination of palladium with gold creates a reliable contact system which needs less gold material than traditional gold plating.

The engineered material known as iON™ cladding systems provides high-reliability electronic applications through palladium-nickel base layers with thin gold overlays that reduce material consumption while maintaining conductivity and highly efficient wear resistance.

Application in Custom Connector Manufacturing and Market Benefits

The implementation of reel-to-reel electroplating in custom connector production enables industrial-scale precision performance and manufacturing efficiency. The technical complexity of the process shows its real value through its integration with the complete production system that includes stamping and tooling and assembly processes. The process serves as an essential base for manufacturing excellence beyond its typical function as a finishing operation.

Integration with Tooling and Stamping

The manufacturing process of custom connectors starts with metal strip stamping that requires precise tolerances for following customer design requirements.

The integration of plating considerations in tooling design enables improved precision in both dimension and metallurgical results. Tooling design combined with plating strategy produces consistent performance results and increased product yield for both fine-pitch contacts and complex carrier strip geometries.

Supporting Modern Connector Demands

Today's electronic devices - alongside vehicles and industrial systems - require connectors that can operate dependably through numerous mating cycles and excel under diverse temperature conditions and corrosive and sterile environments.

Reel-to-reel plating enables manufacturers to tackle these challenges through precise application of appropriate finishes that include conductive, protective or solderable coatings. The nature of this process allows manufacturers to produce high-volume quantities without sacrificing product quality. A single supplier can provide OEMs and tiered suppliers with dependable connector components that reduce supply chain uncertainty and decrease batch-to-batch variations.

Automotive connectors need to work flawlessly throughout a vehicle’s lifetime, all the time enduring vibrations, heat and moisture. Medical and telecommunications connectors need to fulfil stringent regulatory requirements to provide sustained stability throughout their operational period.

Reel-to-reel plating allows manufacturers to treat each contact point according to its specific requirements for materials such as high-conductivity gold, corrosion-resistant palladium or cost-effective tin through a unified and scalable manufacturing process.

Operational and Commercial Efficiencies

There are immediate benefits for both cost efficiency and production lead times. Manufacturers who combine stamping and plating operations cut their operational expenses and streamline their logistics. The single-source accountability system eliminates communication breakdown and speeds up both design changes and engineering query responses.

The quick prototyping capabilities inherent in the process enable businesses to shorten development periods and get products to market more rapidly. High precision and repeatability across production runs starting from prototypes to a million parts reduces the need for additional inspection-intensive validation and downstream rework.

A Proven Platform for Global Supply

Batten & Allen's reel-to-reel plating capability has demonstrated excellence through its 90% international output while achieving successful market results.

Our delivery of plated stamped components to global customers with consistency and confidence rests on this advanced integration of engineering and manufacturing disciplines.

Batten & Allen operates as a trusted partner for OEMs who require high-performance connectors that unite technical superiority with market-friendly economics through reel-to-reel precision.

To find out more about our advanced stamping techniques

Comprehensive GuideYour Reel-To-Reel Stamping Experts

We don’t just stamp – we design, plate, assemble and more, creating a simplified process to meet your demanding production needs.

Start a conversation