Advanced Reel-to-Reel Stamping Techniques: Precision and Speed in Manufacturing

Your Reel-To-Reel Stamping Experts

We don’t just stamp – we design, plate, assemble and more, creating a simplified process to meet your demanding production needs.

The Foundations of Reel‑to‑Reel Stamping

High-volume precision manufacturing depends fundamentally on reel-to-reel stamping. Continuous strip stamping is an efficient manufacturing method that uses unbroken metal strip coils and a succession of tool and die stations to carry out complex component production. The process depends on precision, fast operation and consistent outcomes. It is essential for many advanced industrial applications including electronics, automotive and medical devices.

Understanding the Continuous Flow

Reel-to-reel manufacturing depends on uninterrupted motion. A press stamping operation uses large metal strip coils while the press contains progressive tooling which executes multiple operations including blanking, piercing, forming, embossing and part separation through consecutive stations. The die performs a step-by-step transformation of raw material into finished components through the progressive advancement through the tooling stages.

The continuous processing of metal attached to its carrier strip minimises handling requirements, keeps the alignment accurate and enables precise production of complex geometries in large volumes. After stamping, the metal strip gets re-rolled for further processing including plating, moulding, or separating for assembly purposes.

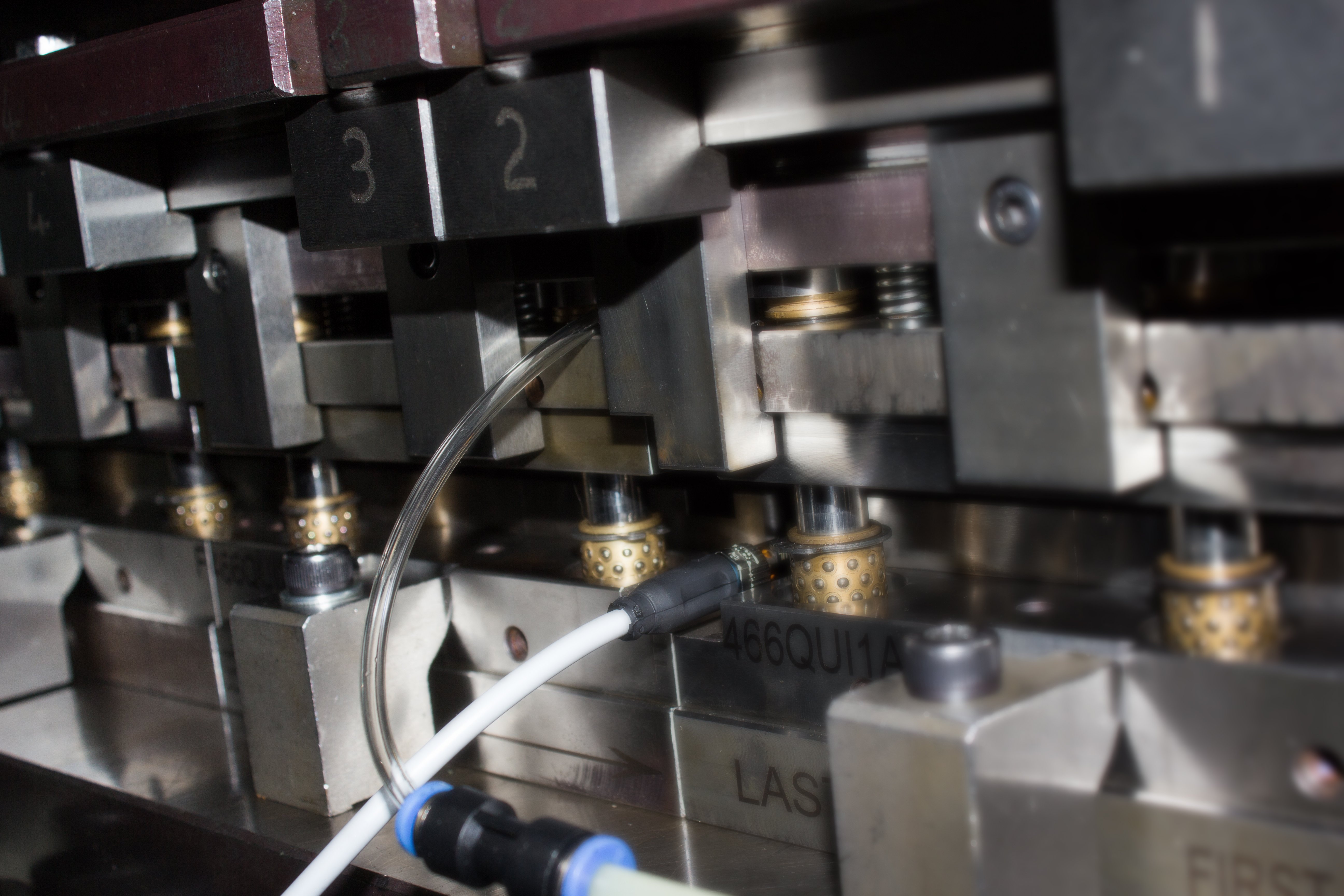

Precision Tooling and Progressive Dies

The reliability of reel-to-reel stamping depends on the standard of tooling materials. The manufacturing of progressive dies requires precise engineering. Each station must align perfectly so consecutive operations can be performed in one continuous stamping process. These dies are built to endure millions of cycles, with tight tolerances and consistent clearances that prevent material deformation or misalignment. The performance of these components depends on precise and regular maintenance of punches and dies – even small amounts of wear will affect their precision.

Operational Considerations: Feed Control and Coil Handling

Achieving this accuracy requires strict management of material handling processes. The feed systems maintain strip position between die cycles through their exact dimensional calibration. The integration of servo-driven systems boosts positional accuracy and allows the system to work with different strip dimensions. Correct synchronisation of feed rates reduces slack, preventing strip jamming and protecting the detailed geometries shaped during previous die operations.

Proper tension control of the coil is essential. When tension is too low, the strip tends to drift from its intended path – but excessive tension can distort the material. The die accepts conditioned material from coil straighteners and unwinders which produce flat and consistent strips throughout their entire length. Pilot-hole indexing and edge guides ensure precise alignment.

A Platform for Complex, High-Volume Production

Large-scale manufacturing benefits hugely from the reel-to-reel approach. It delivers the stability and high-volume production needed for complex component geometries. This precision technology, combined with ongoing quality control, helps manufacturers to meet speed requirements without sacrificing quality and consistency.

Progressive Die Stamping

Progressive die stamping uses sequential operations to maintain precise control from start to finish. The metal strip advances through various tool stations that perform specific operations such as piercing, bending, coining and trimming in sequential order.

Linear motions enable single press strokes to perform multiple operations, producing complex components with consistent results. In progressive die systems, the strip maintains its carrier attachment throughout the process, ensuring proper alignment and enabling stamping to tight tolerances. Large-scale manufacturing operations benefit from this method because it delivers precise results with consistent outcomes. Production facilities gain essential cost efficiency through tooling installation and process calibration, which reduces changeover times.

The progressive die system achieves its highest performance level in manufacturing complex parts that need sequential forming steps. Engineers use the modular structure to break down intricate shapes into smaller production steps across multiple stations. This process is excellent for creating precision contacts and terminals.

Find out more in our comprehensive guide

Optimising for Speed and Performance

To stay competitive, manufacturing requires fast production of complex components. Reel-to-reel stamping is invaluable – and today’s technology transforms it into a high-throughput precision manufacturing system. In this section we will examine the operational improvements that allow stamping systems to achieve high speeds while delivering the essential quality and consistency.

Precision Coil Handling for Continuous Flow

At the core of any reel-to-reel process is the strip itself. How it moves through the line has a direct impact on performance and quality. The stamping process requires automated straighteners which maintain strip alignment and tension at all times. High line speeds of thousands of strokes per minute mean that any feed accuracy deviation can lead to serious issues such as scrap production, tooling damage and misaligned parts.

Advanced feeding systems are equipped with sensors and encoders that monitor every millimetre of movement. These systems adjust in real time to accommodate material inconsistencies, temperature changes or minor equipment wear – ensuring a smooth and controlled feed regardless of external variables.

-1.jpg?width=2000&name=BAJun24Manu%20(72)-1.jpg)

Rapid Tool Change and Set-Up Reduction

The stamping cycle benefits from a straightforward set up – and this extends to other production stages as well. The ability to switch quickly between jobs while minimising disruption is essential for tight production schedules. Automated die change systems transform what used to be a labour-intensive manual process into a fast and consistent operation.

Implementing quick-change tooling and modular die setups lets manufacturers perform batch-to-batch transitions with less downtime, making smaller production runs economically feasible without sacrificing output. The implementation of tool storage and identification systems accelerates the changeover process.

RFID tagging and integrated control systems enable readiness to be verified before production restarts. This ensures correct tooling installation and proper alignment.

Real-Time Monitoring and Intelligent Systems

Speed without control is a risk no manufacturer can take. This is where real-time sensor technology and programmable logic controller (PLC) integration come into play. From monitoring die condition to checking for part ejection and strip positioning, sensors provide constant feedback to the control system. Anything untoward is detected immediately, allowing the line to pause or self-correct before scrap or damage occurs.

Programmable logic controllers act as the nerve centre of the system, coordinating every aspect of the operation. As machines become more connected and intelligent, they offer not only stability at speed but a growing ability to learn, support and adapt predictive maintenance routines. This is crucial for uninterrupted, high-performance production.

Integration of In‑Line Plating and Reel‑to‑Reel Processing

Demand for complex components that require precision forming, conductivity, corrosion resistance, or solderability has made reel-to-reel stamping – integrated with in-line plating – a crucial modern production capability. The combination of forming and finishing operations using this process eliminates multiple handling steps and produces value-added components that can be sent directly from the press to packaging or assembly.

The Benefits of Integration

The electrochemical process of plating metals on to material strips occurs continuously during their movement through a plating line. This integration between forming and plating operations enables the precise application of coatings such as gold, silver, tin, nickel or palladium to electrical contacts, battery components, electromagnetic interference (EMI) shielding parts and more. Lead times become shorter. Quality is monitored closely throughout every stage. This is made easier because the forming and plating operations function as a single automated process.

The main breakthrough in this field has emerged through the development of selective plating technologies. These techniques enable the precise application of coatings to specific regions of the strip, rather than uniform coverage of the entire surface. Selective plating decreases material usage because it focuses on the areas that need it. This method cuts costs and optimises performance in critical areas.

Selective plating requires highly advanced control systems. The combination of masking techniques, laser-defined boundaries, bubble-cell and jet-cell plating systems allows for pinpoint accuracy. The bubble-cell system uses gas bubbles to create plating barriers that limit plating activity to specific strip regions, ensuring fast production and precise finishes. Reel-fed strips can pass through multiple-strand plating chambers to receive multiple coating types or finishes during one production run.

Precise control over temperature levels, current density and dwell time values is vital. The plating integrity of entire production runs depends on modern plating lines that use inline sensors and closed-loop feedback systems for quality control. The tools guarantee uniformity of coating thickness to the micron. The strip needs constant motion. This requires precise alignment of plating stations to match the stamped features. The coil requires a consistent advancement rate. This keeps the stamping phase indexing and strip geometric landmark registration in alignment.

A Winning Combination

The combined manufacturing process produces a ready-for-use re-reeled coil containing stamped and coated components that can proceed to assembly or moulding operations. The uninterrupted production of fully formed and plated components increases both technical and commercial product value when parts proceed to moulding machines for encapsulation or OEM sub-assembly facilities.

It is a great example of precision engineering and manufacturing, integrating functional elements directly into the production workflow.

Quality Assurance, Predictive Monitoring and Continuous Improvement

A fundamental requirement of high-volume reel-to-reel stamping operations must always be consistency. Quality assurance must be integral to the production process, enabling manufacturers to deliver millions of components that meet precise tolerances and quality standards. Leading manufacturers like Batten & Allen achieve and enhance quality benchmarks by combining real-time monitoring with predictive analytics and continuous improvement initiatives.

Integrated Excellence

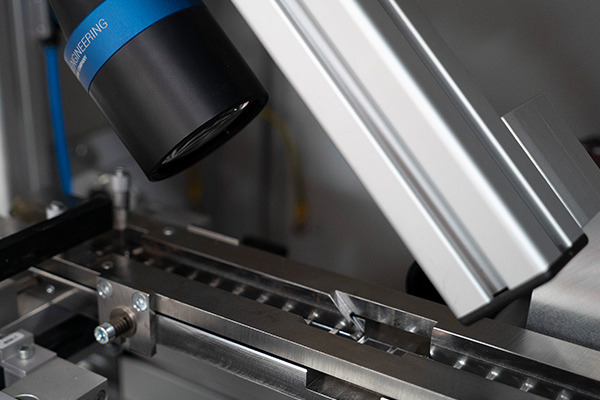

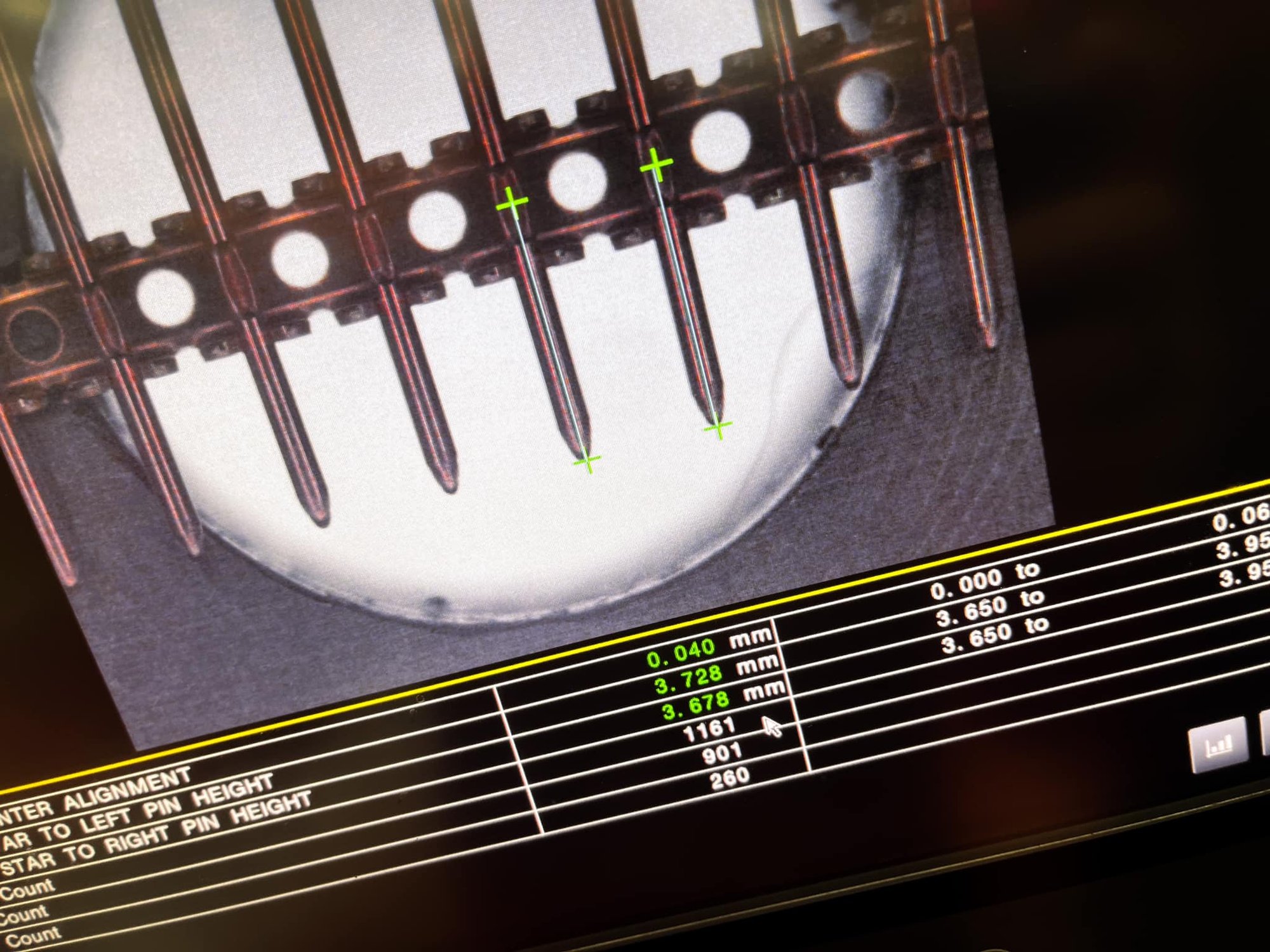

Inline measurement systems provide an essential foundation. Optical sensors, laser micrometer gauges and contact probes located along the advancing stamped strip sections measure vital dimensions including width, thickness, hole alignment and form geometry. Real-time operation allows these systems to detect deviations the moment they happen, enabling immediate process adjustments.

Real-time inspection performed during production allows defective parts to be detected before they accumulate – minimising waste and protecting downstream value.

The Quest for Quality

Vision inspection systems verify that stamped features meet quality standards. High-resolution cameras and sophisticated imaging software enable complete visual inspections of each part to detect surface defects, misfeeds, burrs and incomplete formations.

The systems have programming capabilities that identify sophisticated shapes and match them with master templates for precise anomaly detection that far surpasses human inspection capabilities.

Essential surface-level detection systems monitor mechanical health, protecting tooling equipment and infrastructure. Stamping press sensors track small variations in torque, vibration and acoustic signatures. Tooling component wear and imbalance issues become detectable, allowing maintenance teams to prevent production disruptions. Collected data over time enables organisations to develop predictive maintenance strategies that extend die set longevity and reduce production interruptions.

Towards a Greener Future

Today’s focus is on scrap reduction. The rising cost of raw materials combined with tightening sustainability targets is making companies use their strip material efficiently. Sophisticated nesting algorithms optimise part arrangements inside strip layouts to achieve maximum yield while minimising offcuts.

Small improvements in material efficiency lead to major advantages regarding cost reduction and environmental benefits over the long term. Real-world production data guides the continuous improvement of these layouts, which form part of an ongoing operational lean initiative.

In Summary

At Batten & Allen, quality assurance is an ongoing process. Our reel-to-reel stamping lines operate with inline inspection systems and sensor-based monitoring, together with predictive tooling analysis.

This established infrastructure enables us to uphold strict standards for dimensional precision, operational stability and finish quality at all production levels. Our commitment to automation development and continuous process optimisation helps us to provide components that fulfil stringent industry standards and enable our customers to reduce risk and maximise yields.

Your Reel-To-Reel Stamping Experts

We don’t just stamp – we design, plate, assemble and more, creating a simplified process to meet your demanding production needs.