Stamping Your Mark: Customisation in Metal Stamping

Introduction In manufacturing, the ability to offer customised solutions is a critical requirement for innovation and success. This is especially...

Brands are choosing us to partner with them to bring innovate products to market quickly and cost effectively.

Working on a Prototype and need expert input, why not get in touch and talk with our experts.

2 min read

Batten & Allen Jan 24, 2024 10:35:26 AM

In the intricate world of metal stamping, precision and reliability are more than goals. They’re absolute necessities.

Batten & Allen, a leader in the industry, has an unwavering commitment to these principles. This article explores how Batten & Allen upholds its promise of precision stamping reliability, ensuring that every component they produce meets the highest standards of quality and performance.

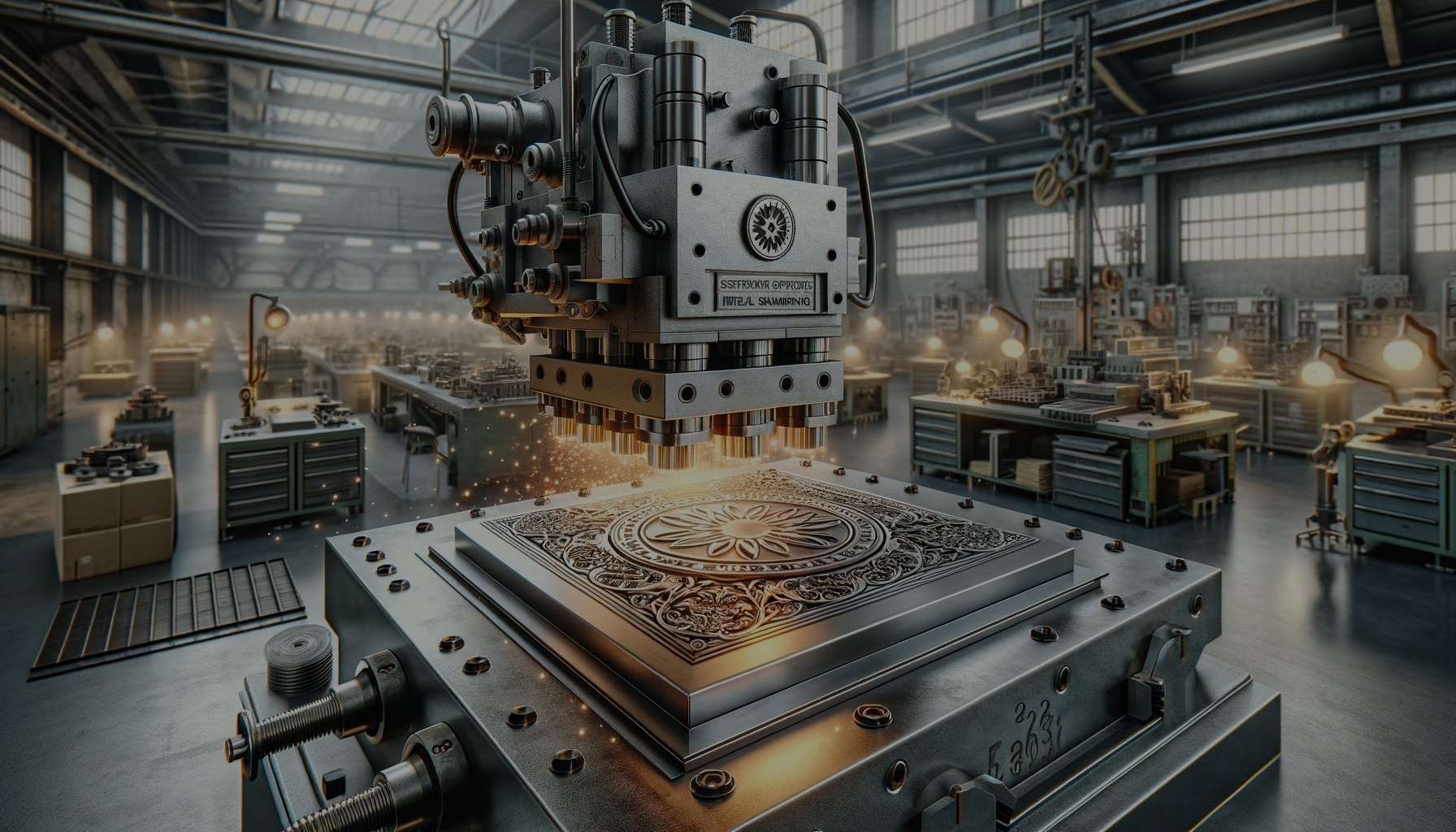

Batten & Allen’s journey towards precision begins with its investment in advanced technology and state-of-the-art equipment. The company invests significantly in high-precision stamping presses and cutting-edge fabrication tools, ensuring that every component is crafted with complete accuracy.

This technological edge is crucial when producing parts with tight tolerances – a non-negotiable requirement in industries like electronics, automotive, and aerospace.

The company’s skilled workforce is a critical component of its success.

Batten & Allen’s team of engineers and technicians are experts in their field, fully and continuously trained in the latest stamping techniques and technologies. This blend of experience and ongoing education ensures that the workforce can adeptly handle the complexities of precision stamping, translating intricate designs into flawless components.

At Batten & Allen, quality control is more than a process. It’s a culture.

The company employs rigorous inspection and testing protocols at every stage of the stamping process. From initial material inspection to final product testing, each component is scrutinised to ensure it meets the required specifications. Advanced quality control methods, such as Statistical Process Control (SPC), are utilised to monitor production processes and maintain high standards of reliability.

Understanding the diverse needs of different industries is a hallmark of Batten & Allen’s approach. The company tailors its stamping solutions to meet the specific requirements of each sector it serves.

Whether it’s producing high-strength components for the automotive industry or intricate parts for electronic devices, Batten & Allen’s ability to customise its processes is key to its reliability promise.

Innovation is at the core of Batten & Allen’s operations.

The company is constantly exploring new methods and technologies to enhance its stamping processes. This commitment to innovation, coupled with a philosophy of continuous improvement, ensures that Batten & Allen stays ahead of industry trends and consistently delivers products that set the standard in precision and reliability.

Batten & Allen also recognises the importance of sustainability in manufacturing. The company adopts eco-friendly practices in its operations, including efficient use of materials, waste reduction, and energy-saving measures.

This responsible approach not only minimises the environmental impact of their operations but also contributes to the overall efficiency and cost-effectiveness of their stamping processes.

By integrating sustainability into their business model, Batten & Allen demonstrates a commitment to future generations while maintaining the highest standards of precision and reliability.

The Batten & Allen promise of excellence is firmly rooted client relationships. By consistently meeting and exceeding client expectations, the company has established itself as a trusted partner in the metal stamping industry.

Their approach to client service, characterised by open communication, responsiveness, and a deep understanding of client needs, further cements their reputation as a reliable and customer-focused operation.

Through a combination of advanced technology, skilled workforce, stringent quality control, and continuous innovation, Batten & Allen delivers on its promise of precision and reliability in every component they produce.

As they continue to lead and innovate in the metal stamping industry, their dedication to quality, sustainability, and client satisfaction remains unwavering, setting a benchmark in the field.

Ready to learn more about reliability metrics? Read on here…

Introduction In manufacturing, the ability to offer customised solutions is a critical requirement for innovation and success. This is especially...

Rigorous Quality Requirements of the Aerospace Sector Aerospace has some of the most demanding requirements of any industrial sector when it comes to...