Advanced Technology Integration

Using state-of-the-art machinery to ensure each component fits perfectly.

Brands are choosing us to partner with them to bring innovate products to market quickly and cost effectively.

Working on a Prototype and need expert input, why not get in touch and talk with our experts.

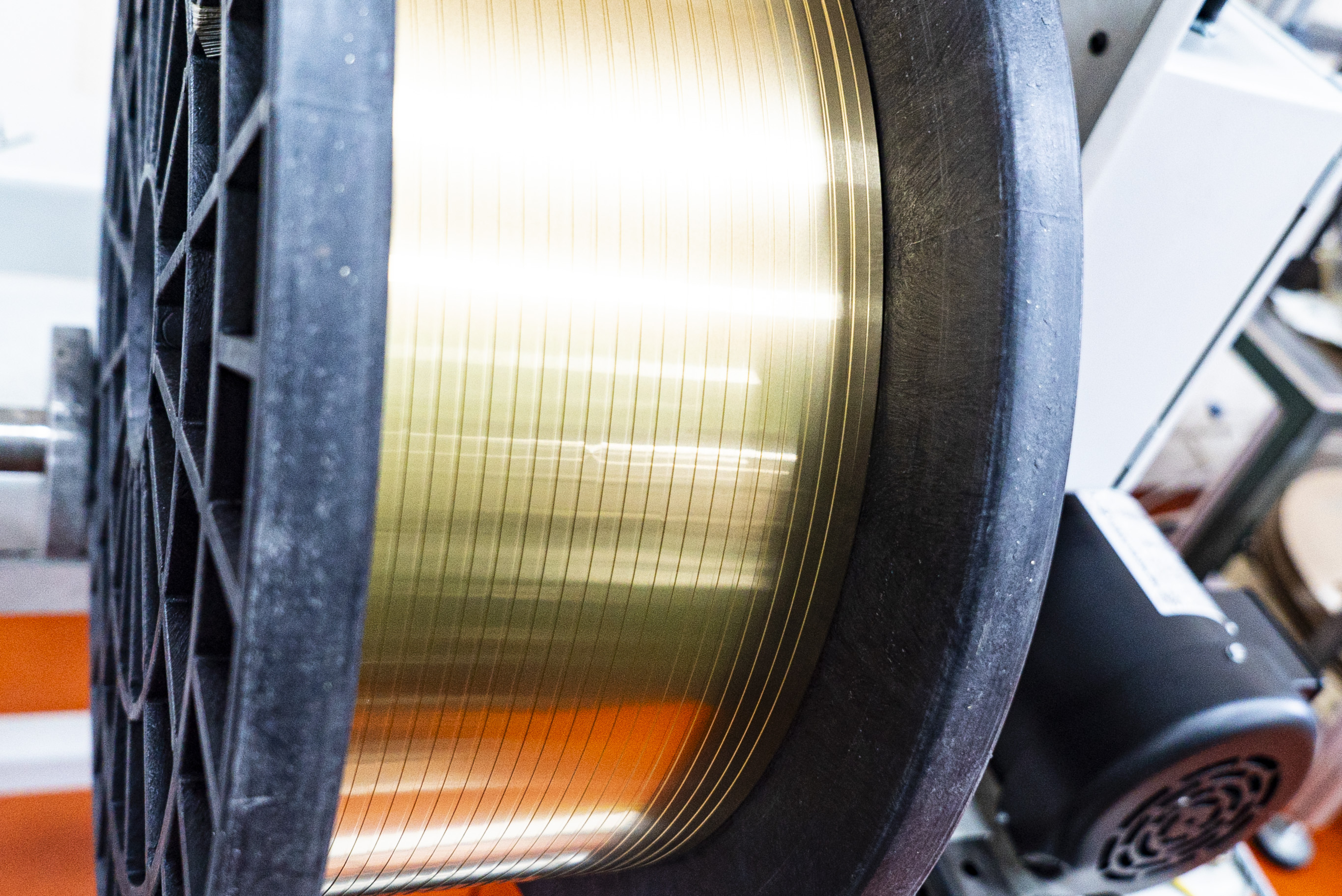

At the heart of Batten & Allen’s manufacturing capability is our reel-to-reel stamping process - a high-speed, high-volume solution for delivering precision components with true quality and repeatability. With over 85% of our business revolving around this advanced method, reel-to-reel is very much the foundation of our work.

Reel-to-reel stamping is a high-speed manufacturing process where a continuous strip of metal is fed from one reel, stamped into precision components using progressive tooling, and then rewound onto another reel.

Reel-to-reel stamping is ideal for electronics and lead frame applications, where cost efficiency, speed and precision are vital. We work with a wide range of materials, including copper alloys and nickel iron, delivering billions of units with fine tolerances and clean finishes.

We design and build our own tools, manage in-line inspection systems, and operate 22 presses, three of which currently incorporate some form of automated inspection. This includes dimensional checks, damage detection and critical feature validation, configured according to your product’s specifications.

Recent advancements include the implementation of multi-coil winders (automating reel changes and increasing operator efficiency), as well as highly accurate auto-dosing systems that apply lubricants only where required. This level of control improves part cleanliness and downstream process compatibility.

This not only lowers costs but also reduces waste and simplifies post-production operations. In fact, when customers come to us with a design intended for loose piece stamping, we frequently recommend converting it to a reel-to-reel format - adding long-term value to their process.

Batten & Allen's tailored assembly process is a great example of how we operate. Here's what sets us apart:

Using state-of-the-art machinery to ensure each component fits perfectly.

Every project undergoes rigorous planning to ensure seamless execution and alignment with client requirements.

Our team brings a blend of expertise and experience, ensuring every assembly is of the highest quality.

We believe in the power of partnership. Our team collaborates closely with clients, incorporating feedback and adjusting to meet unique project requirements.

Our approach is not static. Using data insights, we fine-tune the assembly process, aiming to exceed client expectations with each project.

Through our commitment to precision, technology, and collaboration, Batten & Allen consistently delivers products that surpass client expectations.

For Batten & Allen, the ideal partner is not just a client, but a collaborator, invested in the pursuit of precision and innovation. They value cutting-edge technology and expertise, understanding the importance of each step in the assembly process. They are open to feedback, pro-active in identifying opportunities for improvement, and share our commitment to quality and precision.

Our team of engineering experts follow a tried and tested assembly process. We combine skill and knowledge creating precision results every time.

A key part of how we work is in our planning stages. Working collaboratively, we ensure you receive the best product at the best price.

Batten&Allen thrive on the variety our customers provide. Each job is carefully assessed and processsed. This involves eveything from the intial quote through to completion and dispatch.

We're not just a component supplier. At Batten & Allen we collaborate on every order. This makes sure you are fully aware of the assembly process at all times. It also keeps us informed of any adjustments which need to be made.

Smooth, uninterrupted, and efficient Our assembly systems create a continuous production process, Fast, accurate and totally reliable

At Batten & Allen we pride ourselves on being able to respond to customer requirements quickly. We understand that things can change. We're happy to oblige wherever possible

Dive into Batten & Allen's journey of mastering tooling design, ensuring reliability at every stage. Our in-house capabilities, from advanced wire erosion to state-of-the-art machining centers, showcase our commitment to delivering high-quality components efficiently.

Learn how our meticulous design process, combined with our expertise in stamping and plating, offers unparalleled precision and cost-effectiveness.

Read the Full Case Study on Tooling DesignWe don’t just stamp – we design, plate, assemble and more, creating a simplified process to meet your demanding production needs.

Start a conversation