- Reel To Reel Stamping

- Tooling

- Progression

Progression

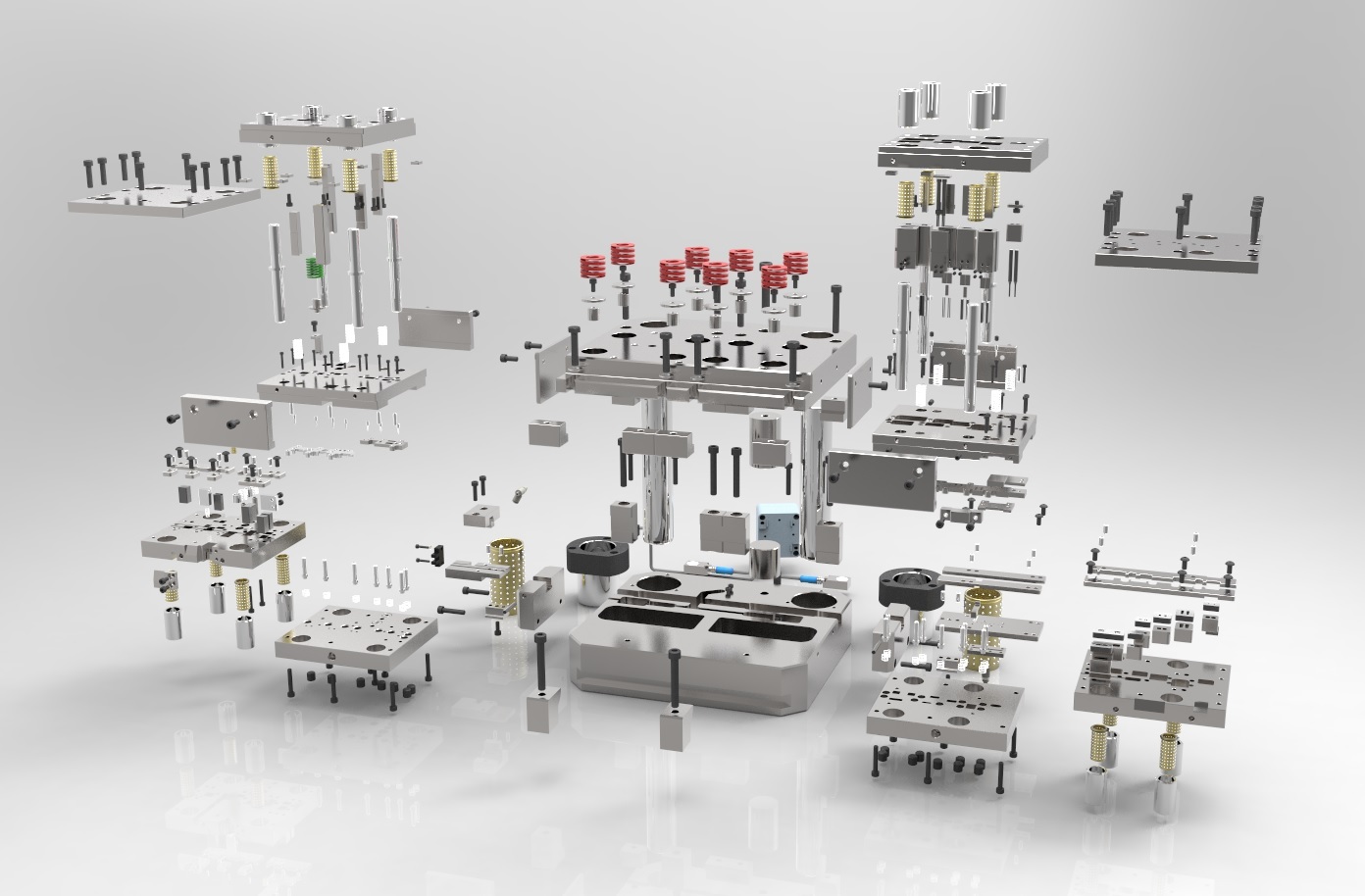

100% In-House Tooling For Quality, Consistency and Accountability

All tooling work at Batten & Allen is carried out in-house. No tooling is subcontracted. This ensures optimal quality, tool longevity and efficiency every time.

Keeping everything in-house gives us full control from start to finish. Unlike subcontractors who do not make the tooling they use, we have a vested interest in ensuring that every tool is the best it can possibly be. No corners are cut. Every tool is built to last – and at cost to maintain sensible pricing for you.

With our extensive design for manufacturing expertise, we can suggest subtle tooling changes that will enhance quality, extend tool life, cut costs and improve your return on investment at each pitch/feed length.

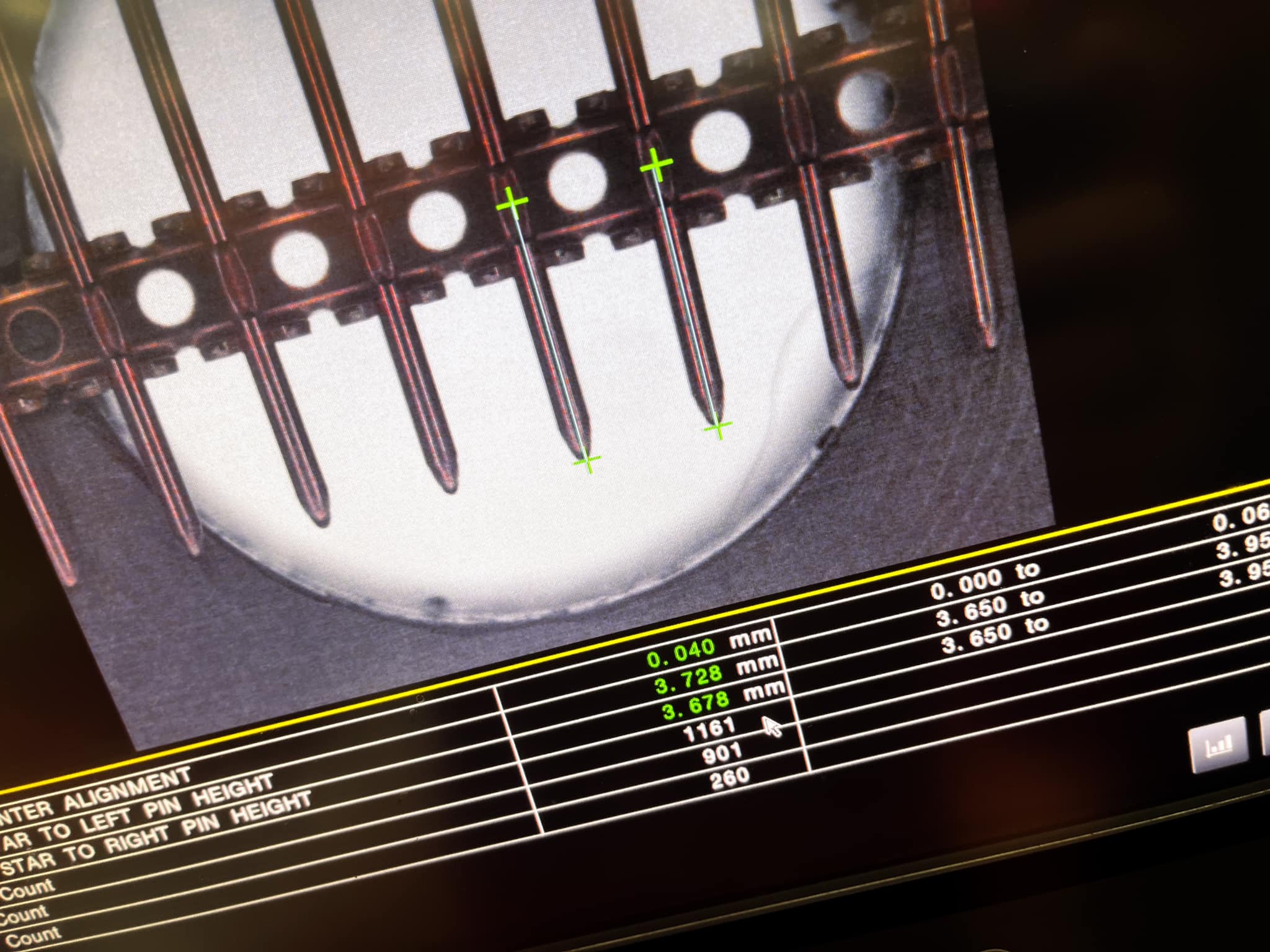

Absolute Control Over Precision And Quality

At the production stage, we’re often dealing with high-speed, high-volume production of complex parts. Any potential deviation in tool geometry, alignment or wear behaviour could lead to misfeeds, burrs and ultimately failed parts. When tooling is in-house, we control every micron of the build and every hour of the tool’s run-in. That level of quality assurance simply cannot be matched by an external supplier working to looser tolerances or broader delivery windows.

Speed of Iteration and Continuous Improvement

When everything is in-house, the feedback loop between toolmaking, stamping and plating is immediate. This agility minimises downtime and improves efficiency. Changes can be trialled quickly. No subcontractors means no delays due to third-party modifications.

Intellectual Property and Confidentiality

In many multi-million-part contracts, progression tool design is a major part of our competitive advantage. We are often working with geometries, materials or plating techniques that help to give our customers a competitive edge. By keeping tooling internal, we protect our IP and eliminate the risk of critical know-how leaking to competitors or other subcontractors.

Tool Longevity and Cost Efficiency

Tool life is directly linked to the quality and frequency of monitoring and maintenance. Our in-house teams are best positioned to keep tools at peak performance – applying preventative maintenance, tracking cycle counts and understanding wear patterns. Subcontracted tooling is often treated as transactional: built to spec, shipped out and forgotten. In-house tools, by contrast, are well maintained assets under our stewardship.

Customer Confidence and Compliance

Customers awarding large contracts demand traceability, consistency and a partner who can take full ownership. Telling a Tier 1 aerospace, automotive or electronics client that tooling is being subcontracted would quite rightly raise red flags. It would introduce uncertainty in lead times, tolerances and process control. Keeping everything in-house demonstrates operational maturity and a commitment to process integrity.

Tooling isn’t just a cost – it’s a capability. At the progression stage, when margins are tight and expectations high, we embed that capability within the four walls of our business to deliver repeatable, reliable results at scale.

Case Study

Precision tooling excellence: from prototype to production

Dive into Batten & Allen's journey of mastering tooling design, ensuring reliability at every stage. Our in-house capabilities, from advanced wire erosion to state-of-the-art machining centers, showcase our commitment to delivering high-quality components efficiently.

Learn how our meticulous design process, combined with our expertise in stamping and plating, offers unparalleled precision and cost-effectiveness.

Read the Full Case Study on Tooling DesignNews and insights

Everything about the market, Batten & Allen and the services we offer to give you the competitive edge.

2 min read

New ‘Tube Map’ Online Resource For Stamped/Plated Components

Batten & Allen: Aug 29, 2025

Infographic: Batten & Allen's Turnkey Process From Concept to Delivery

Batten & Allen: Jan 13, 2025

Embark on a Precision Journey

Discover the synergy of precision, technology, and collaboration with Batten&Allen.

Talk to an expert