Advanced Technology Integration

Using state-of-the-art machinery to ensure each component fits perfectly.

Brands are choosing us to partner with them to bring innovate products to market quickly and cost effectively.

Working on a Prototype and need expert input, why not get in touch and talk with our experts.

Compliance-critical sectors such as electronics, aerospace and automotive rely on Batten & Allen for consistent and dependable packaging of their sensitive stamped and plated components.

Smart packaging solutions are essential in:

Industries best suited: Electronics (connectors), automotive sensors, telecoms.

Description: Components remain connected to a continuous stamped strip and are wound on to reels. This format is typically used for reel-to-reel plating and automated insertion processes.

Some 85% of our products are packaged in reels. They can weigh from 1 to 15 kg and can contain 5,000 to 100,000 parts.

Our standard reel diameters used for surface mount and precision components are: 610 mm (24") and 700 mm (27.5")

Advantages: Reels provide good protection and support high-speed automated production. Compatible with reel-to-reel plating and final forming operations. Offers high throughput and consistency.

Disadvantages: Requires specialised downstream tooling to cut and form parts during final assembly.

Industries best suited: Electronics (especially surface-mount technology), automotive ECUs, aerospace avionics.

Description: Components are sealed in individual pockets on a continuous strip of carrier tape wound on to a reel. Designed for automated assembly lines using pick-and-place machinery.

Advantages: Tape and reel allows for high-speed, automated assembly and ensures precise orientation of components. It offers excellent protection during transport and storage, especially when paired with anti-static materials. The format is space-efficient and cleanroom-compatible.

Disadvantages: Initial tooling for custom carrier tape can be expensive, additional processing and packaging steps are required. It’s suitable only for small to medium-sized components with regular shapes. Mishandling can cause the cover tape to peel. Incorrect orientation can lead to misplacement in automated systems.

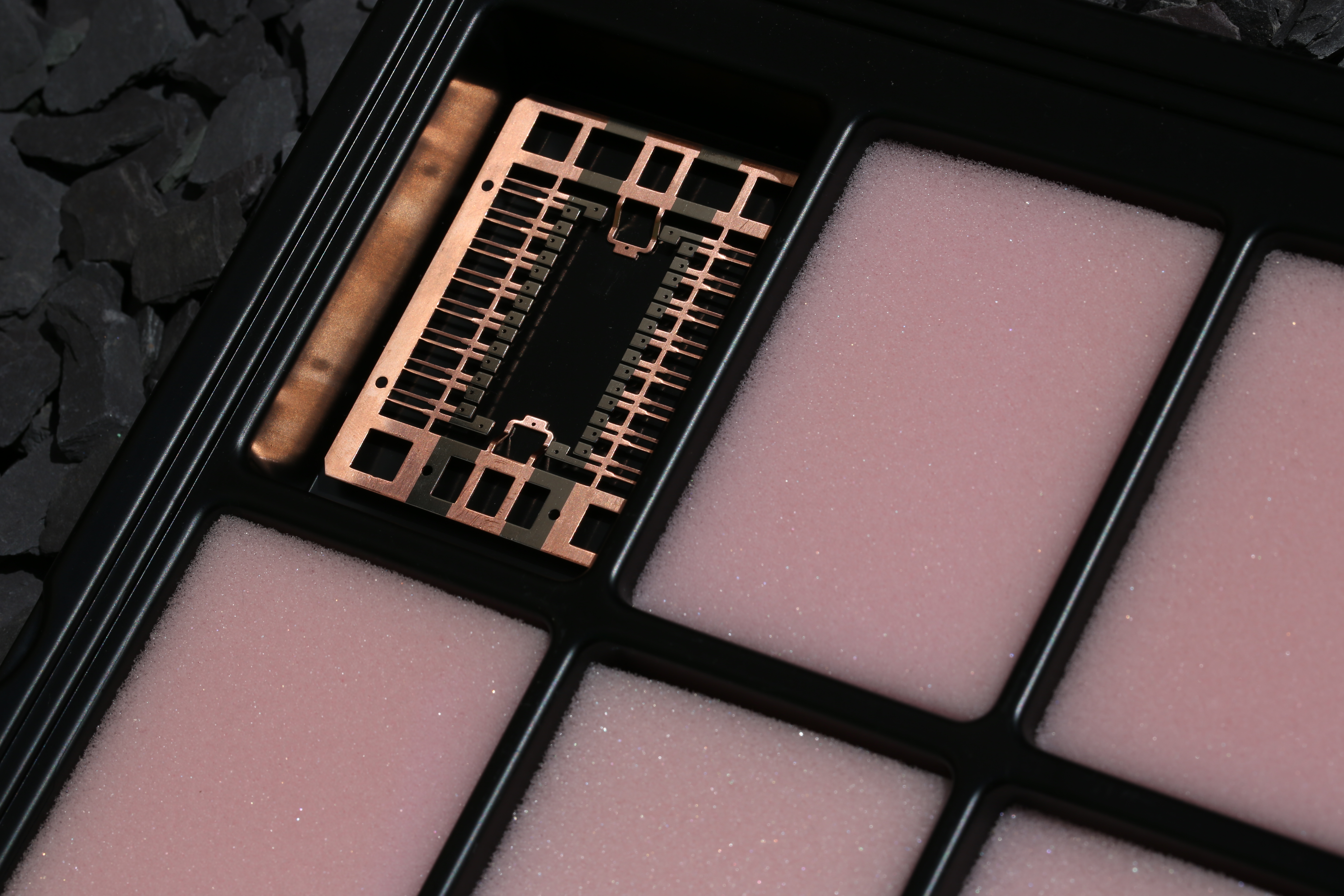

Industries best suited: Aerospace, medical devices, automotive Tier 1 suppliers, high-specification consumer electronics.

Description: Custom-formed plastic trays or sealed blister packs that hold each component in a defined recess to prevent movement or contact.

Advantages: Ideal for components with cosmetic finishes or critical tolerances, especially plated parts that must not rub or clash. Trays can be conductive or antistatic, and they support both manual and robotic handling. They offer excellent visibility and segregation.

Disadvantages: Trays take up more storage space and can be more costly to ship compared with reels. Without careful design, they may not align well with robotic pick-up systems. Trays that are not returnable can also add to environmental waste unless recyclable options are used.

Industries best suited: Heavy automotive, industrial machinery, white goods, general manufacturing.

Description: Components are packaged in cartons with protective layers such as foam inserts, card dividers or sealed bags. Desiccants and corrosion inhibitors may be added.

Advantages: More economical for larger, robust components or where cosmetic quality isn’t critical. Suitable for high volumes and components not destined for automated handling. Offers flexibility in box sizes and shipping methods.

Disadvantages: High risk of parts rubbing together or becoming scratched during transit if not properly separated. Not suitable for fragile finishes or tight tolerance parts. Bulk handling also slows down manual loading at the production line and is generally not automation-friendly.

Batten & Allen's tailored assembly process is a great example of how we operate. Here's what sets us apart:

Using state-of-the-art machinery to ensure each component fits perfectly.

Every project undergoes rigorous planning to ensure seamless execution and alignment with client requirements.

Our team brings a blend of expertise and experience, ensuring every assembly is of the highest quality.

We believe in the power of partnership. Our team collaborates closely with clients, incorporating feedback and adjusting to meet unique project requirements.

Our approach is not static. Using data insights, we fine-tune the assembly process, aiming to exceed client expectations with each project.

Through our commitment to precision, technology, and collaboration, Batten & Allen consistently delivers products that surpass client expectations.

For Batten & Allen, the ideal partner is not just a client, but a collaborator, invested in the pursuit of precision and innovation. They value cutting-edge technology and expertise, understanding the importance of each step in the assembly process. They are open to feedback, pro-active in identifying opportunities for improvement, and share our commitment to quality and precision.

Our team of engineering experts follow a tried and tested assembly process. We combine skill and knowledge creating precision results every time.

A key part of how we work is in our planning stages. Working collaboratively, we ensure you receive the best product at the best price.

Batten&Allen thrive on the variety our customers provide. Each job is carefully assessed and processsed. This involves eveything from the intial quote through to completion and dispatch.

We're not just a component supplier. At Batten & Allen we collaborate on every order. This makes sure you are fully aware of the assembly process at all times. It also keeps us informed of any adjustments which need to be made.

Smooth, uninterrupted, and efficient Our assembly systems create a continuous production process, Fast, accurate and totally reliable

At Batten & Allen we pride ourselves on being able to respond to customer requirements quickly. We understand that things can change. We're happy to oblige wherever possible

Dive into Batten & Allen's journey of mastering tooling design, ensuring reliability at every stage. Our in-house capabilities, from advanced wire erosion to state-of-the-art machining centers, showcase our commitment to delivering high-quality components efficiently.

Learn how our meticulous design process, combined with our expertise in stamping and plating, offers unparalleled precision and cost-effectiveness.

Read the Full Case Study on Tooling DesignEverything about the market, Batten & Allen and the services we offer to give you the competitive edge.

Batten & Allen: Feb 19, 2026

Batten & Allen: Aug 29, 2025

Batten & Allen: Jan 13, 2025

Discover the synergy of precision, technology, and collaboration with Batten&Allen.

Talk to an expert