How In-House Reel-to-Reel Stamping and Electroplating Streamline Production

Your Reel-To-Reel Stamping Experts

We don’t just stamp – we design, plate, assemble and more, creating a simplified process to meet your demanding production needs.

-1.jpg?width=3435&height=2294&name=BAJun24Manu%20(72)-1.jpg)

Integrated Production: From Reel to Finished Component

Efficient manufacturing depends on precise, controlled production throughout each stage of the process. The integration of reel-to-reel stamping with electroplating under one roof eliminates the inefficiencies that can appear when production is split across different locations. The single-site manufacturing method decreases material handling steps while maintaining uniformity and prevents delays that can occur when third parties are involved.

A Turnkey Workflow

The standard production process involves stamping components in one facility before sending them to another location for plating followed by finishing at a different site. Multiple handovers create multiple opportunities for components to become damaged while also exposing them to contamination, delays and quality issues. A fully in-house process eliminates all points of friction that can happen between departments. Coiled strip material enters the facility and undergoes a precisely controlled production sequence that includes precision stamping and selective or full electroplating before completion with final assembly when required. This continuous flow enables more consistent production and faster delivery.

At Batten & Allen, being able to control all stamping and plating at just one location helps our teams coordinate their work in real time. Problems can be quickly solved along with any technical or logistical issues. The setup provides immediate adaptability to changes in demand, new product launches and urgent design modifications.

Control and Accountability

It’s easy to see why a plant that performs tooling, stamping and plating functions together achieves higher quality standards while maintaining complete transparency throughout. The in-house team maintains complete responsibility for quality standards and delivery times since they do not depend on external suppliers. The combination of in-line inspection, real-time process monitoring and unified documentation enables higher standards of output and product consistency.

Internal quality checks provide exceptional value to industries that need to follow strict traceability and compliance standards. The ability to monitor every stage of production with verified control helps gain regulatory approval and customer trust by eliminating subcontractors.

Eliminating Delays and Hidden Costs

The apparent cost benefits of outsourcing frequently hide additional expenses related to freight handling, downtime and repeated quality inspections. All operations contained within a single location minimise these additional expenses in that the process does not require courier coordination, quality protocol reconciliation or transit and inspection time penalties.

The integrated reel-to-reel manufacturing system delivers better production flexibility and maintains a smooth output increase process. Order volume can change, and new product variants can be handled by the facility without needing contract renegotiations or site relocation of production operations. The result creates a robust and cost-effective manufacturing process that leads to future readiness and customer confidence.

Precision and Consistency with Advanced Electroplating Lines

Maintaining accuracy and consistency in high-volume manufacturing environments requires systems designed not only for scale but also for control. Modern reel-to-reel electroplating technology provides this, allowing coatings to be applied with extraordinary precision, even at exceptionally fast processing speeds.

Engineered for High-Speed Accuracy

Today, advanced electroplating systems aren’t limited by the trade-off between speed and precision. A prime example of this is the new generation of selective electroplating lines. This system combines multiple short plating cells with state-of-the-art engineering to achieve exceptional control over deposit thickness and coverage. This modular cell design minimises chemical turbulence, ensures consistent exposure times and allows tighter tolerances to be achieved, even at high volume.

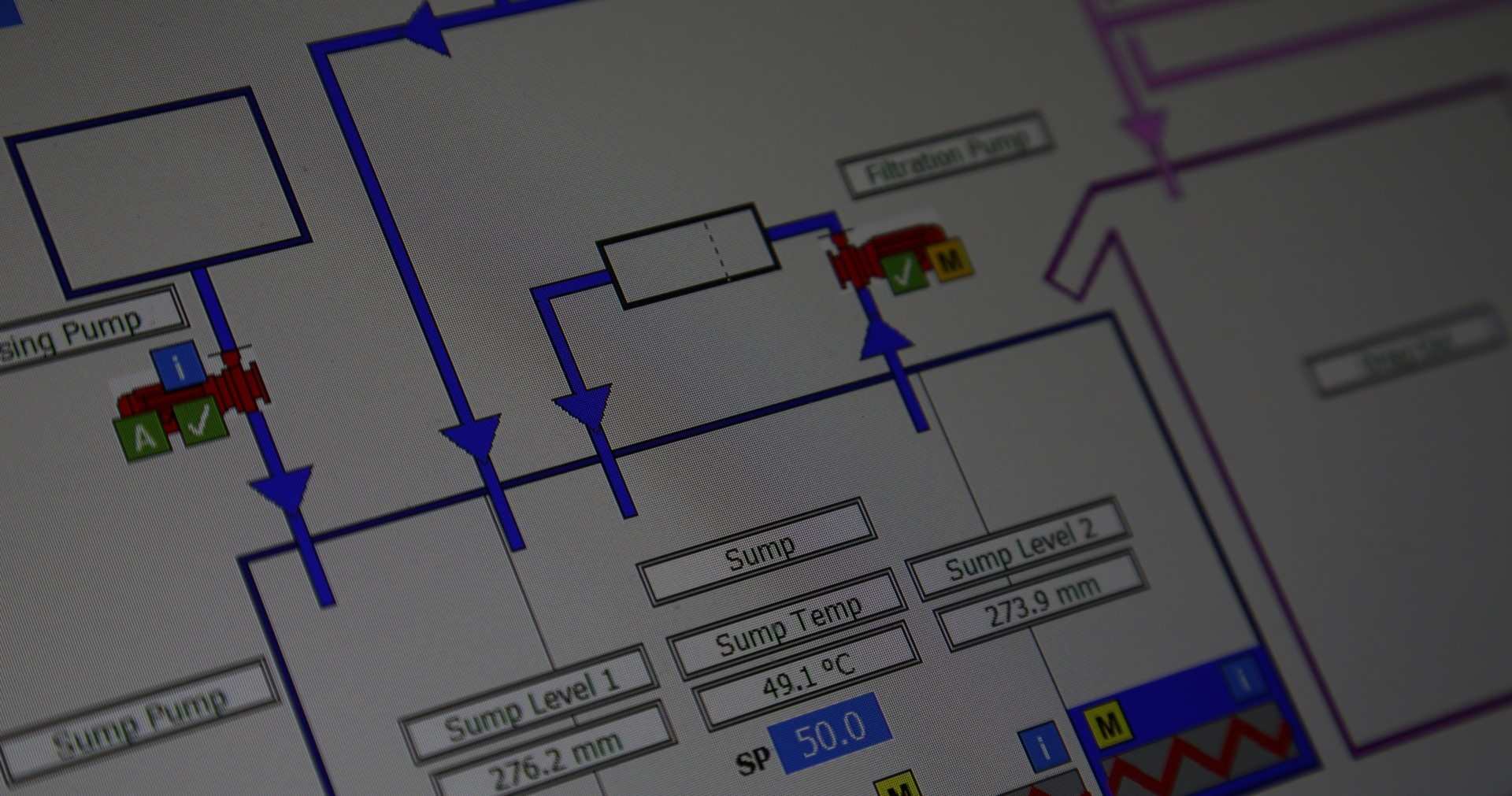

At speeds of up to 750 parts per minute, it becomes essential to monitor and adjust variables in real time. New tech lets teams track every aspect of the plating process in situ, from temperature and flow rates to current densities and pH levels. Adjustments can be made even during production to prevent variation and reduce waste.

Uniform Coating at Scale

Electroplating consistency is not just a matter of aesthetics. It has direct implications for component performance, especially in sectors where electrical conductivity or corrosion resistance is critical. Uneven plating can result in failure, rework, or customer returns. With advanced system controls in place, coating thickness can be held to tightly defined tolerances across every reel, regardless of batch size.

These systems allow for the use of selective plating techniques that only coat areas essential to the function of the component. This not only ensures performance but also maximises the use of costly precious metals such as gold or silver. By targeting deposition exactly where it's needed, material costs are managed without compromising reliability.

Designed in Collaboration

Another important factor in achieving repeatable quality is the alignment between engineering design and plating system configuration. By working closely with in house design and tooling teams, electroplating lines can be calibrated to support specific component geometries, materials, and end-use requirements.

Cost Efficiency through Selective and Pre‑Plating Methods

The advantage of reduced costs combined with quality is a fundamental requirement for all manufacturers. Selective and pre-plating methods within reel-to-reel production allows manufacturers to supply quality components which fulfil today’s application requirements without spending excessively on materials or processing. Selective and pre-plating are most beneficial when operating with a continuous strip because speed along with repeatability and process control drive overall efficiency.

Targeting Value with Selective Plating

Precious metal coatings such as gold, silver and palladium receive selective application to functional areas through this refined plating method. The plating method targets specific contact zones together with functional surfaces that need conductivity protection or wear resistance. The selective plating method both maintains product performance features while minimising the number of expensive materials required.

Different techniques including spot plating, stripe plating and controlled depth plating. All provide customised benefits according to the design shape and intended use of components. The spot plating process applies material to microscopically specific areas that often display intricate details. The stripe plating technique creates continuous metal bands which work best for components with a straight contact interface. Plating at controlled depths maintains uniform thickness for exact electrical standards and dimensional requirements. The precise nature of these techniques makes them suitable for automated reel-to-reel production because the system can achieve micron-level precision when processing thousands, even millions of components.

Manufacturers who restrict plating operations to functional areas make major savings in precious metal expenditure. The volatility of metal markets requires this control system which simultaneously minimises present-day costs while reducing future supply planning issues. This approach means manufacturers can enhance environmental stewardship as it minimises resource usage and waste.

Pre-Plating for Streamlined Processing

The process of pre-plating involves finishing the raw strip material before stamping. This can achieve greater consistency, and the production line becomes fully integrated in-house, as it eliminates the need for post-production plating. This process results in decreased manual handling and diminished product harm while achieving much faster production speeds.

The main advantage of pre-plating is its ability to create uniform results. Raw flat strip material provides a superior surface for plating as it delivers a more uniform thickness and coverage spec compared to shaped or formed components. The plated layer stays intact in critical areas thanks to exact tooling and process control which prevents deformation during stamping.

This approach works best for components needing uniform electrical contact surfaces and consistent appearance. The plating process takes place before forming operations, so parts remain untouched throughout the production sequence. The eliminated production stages directly produce savings for time and workforce while reducing expense.

Precision with Purpose

The integration of selective and pre-plating processes within a reel-to-reel system enables manufacturers to match material consumption with product operational spec. All procedural steps operate with optimised performance to prevent unnecessary repetition. The integrated outcome of purposeful engineering results from in-house control which ensures cost efficiency.

Enhanced Performance and Industry Compliance

Manufacturers like Batten & Allen, who produce components for technically demanding sectors such as electronics, automotive, aerospace and telecoms technology, must meet rising standards of performance, regulatory and quality compliance. In-house reel-to-reel stamping and electroplating provides a controlled, repeatable, and certifiable environment in which to meet these expectations. From enhanced technical performance to traceable process documentation, this approach brings measurable advantages across both production and compliance.

Technical Benefits of Advanced Surface Finishes

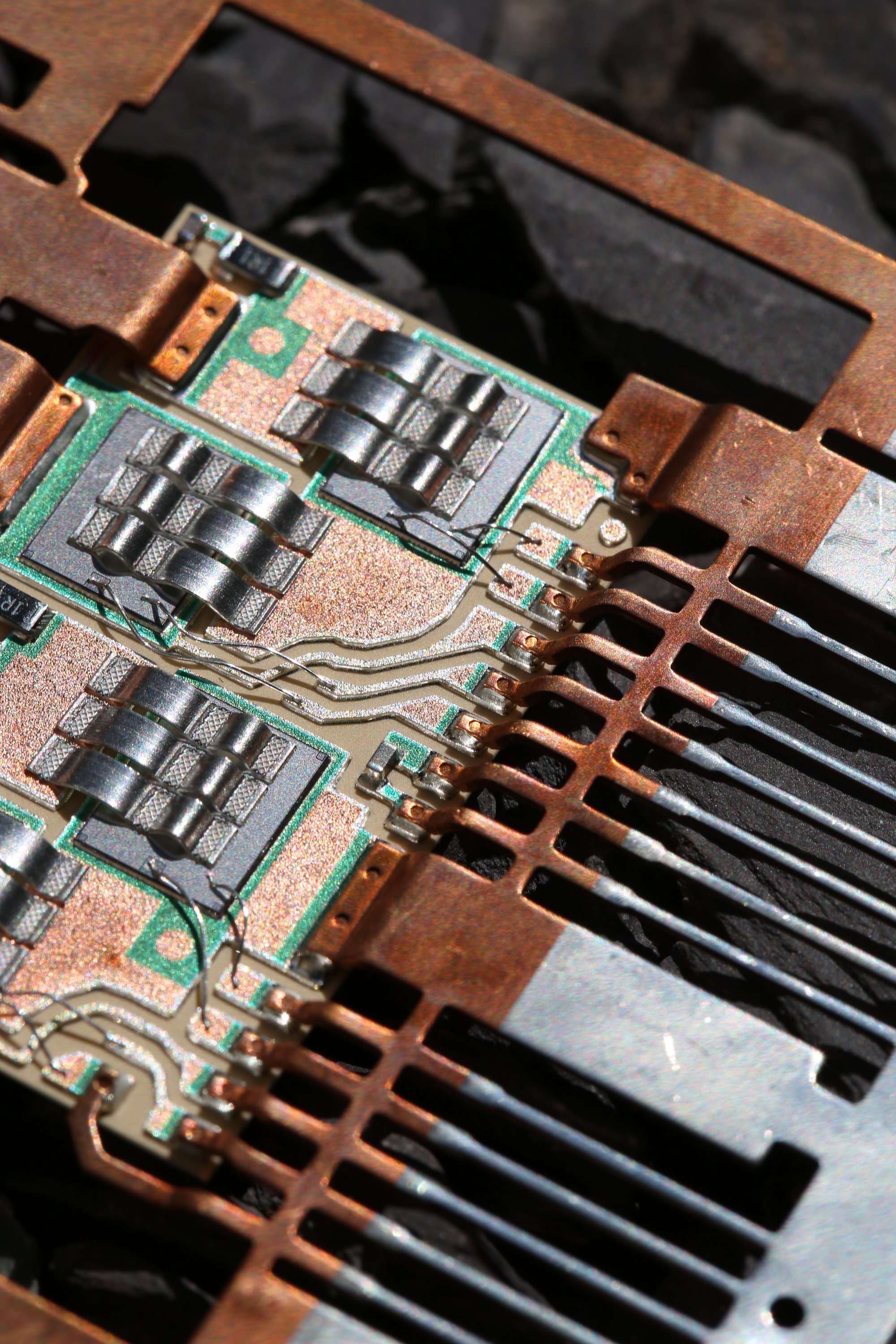

The ability to apply a broad range of metal finishes such as tin, nickel, copper, gold and silver directly onto stamped components allows for a high degree of functional optimisation. The finishes provide essential benefits for corrosion resistance, electrical conductivity and surface durability, vital in sensitive or high-reliability environments.

Gold and silver are ideal for connector and sensor materials because they maintain both conductivity and anti-corrosive properties. Nickel serves well as a material for automotive terminals because it is exceptionally hard-wearing.

Tin serves as an economical surface finish that allows soldering for electronic applications. Meanwhile, the reel-to-reel format enables uniform surface coating across the entire production run which results in reliable and robust large-scale manufacturing.

Where performance requirements are demanding, the use of selective plating within this setup ensures these advanced finishes are used economically and precisely, only where required, and without compromising the integrity of the base material or the finished component. The result; a consistently high-performance output.

Meeting Industry and Regulatory Standards

The manufacturing environment for reel-to-reel production needs to meet international quality standards in addition to technical performance requirements. The manufacturing environment must comply with RoHS for hazardous materials and IATF 16949 for automotive production and ISO 9001 for general quality management and ISO 13485 for medical devices. Maintaining compliance with these frameworks requires detailed process monitoring, documentation, and traceability throughout the production cycle. In-house electroplating and stamping operations can be configured to do just that.

When processes are managed under one roof, data can be captured and validated in real time, with clear links between material input, processing parameters, and final component characteristics. The production process integrates certification and test data as an essential component rather than treating it as a distinct post-production requirement.

In-house analysis and QA measures strengthen compliance procedures, and the continuous monitoring of plating thickness, adhesion and chemical composition enables verification against customer and industry requirements. These checks are not only used to verify compliance but to optimise processes proactively thus reducing the risk of defects.

The integration of compliance practices into the production line ensures manufacturers remain highly agile in response to evolving standards and customer audits. Whether producing micro-scale stamped components for wearable medical devices or high-current terminals for electric vehicles, this capability allows performance to go hand-in-hand with certification—without compromising production speed or flexibility.

Design Collaboration and Sustainability Advantages

Bringing design and manufacturing teams together early in the development process is a powerful way to improve outcomes, reduce waste, and streamline production. In-house reel-to-reel stamping and electroplating environments create the ideal conditions for this kind of cross-functional collaboration, allowing engineers, tooling experts, and plating specialists to work together from the very first prototype. This integrated approach enables design for manufacturability (DFM) to be addressed upfront, ensuring components are optimised not just for performance, but for efficiency and sustainability as well.

Cross-Functional Design from Concept to Production

When stamping and plating are treated as separate, sequential processes, often managed by different suppliers, opportunities for design efficiency are sometimes missed. Tooling complications and selective plating difficulties can be prevented by addressing problems early in the process. Design teams working together with tooling and plating teams help prevent these issues. Yet another benefit of the turnkey solution.

Engineers who collaborate can assess essential design aspects including plating zones, contact areas, edge tolerances and feed hole positioning with direct input from the team responsible for component development. Real-time adjustments help plating masks match stamping dies which decreases the risk of over-plating and misalignment.

This prototype development feedback system allows modifications to be made before starting large-scale production which saves time and resources and reduces costs. The system enables collaboration because it maintains a uniform strip format throughout the entire production process. The coil receives plating and stamping and inspection processes consecutively without requiring multiple transfers. This simplifies tolerance management and maintains process consistency.

Built-In Sustainability Benefits

This approach also delivers substantial environmental gains. With all stages of production under one roof, unnecessary transportation between facilities is eliminated, cutting emissions and lead times. The result is a leaner, more environmentally conscious operation with fewer variables to manage and less waste to process.

In reel-to-reel plating, sustainability starts with smart chemistry management. Advanced plating lines now incorporate closed-loop rinse systems, designed to minimise water consumption and eliminate discharge of contaminated scrub water. Precious metal recovery systems ensure that excess material is not wasted, while chemistry monitoring tools help maintain bath conditions without requiring frequent purging or disposal.

The process of selective plating operates sustainably because it delivers precise amounts of material to specific locations. The combination of design for manufacturing (DFM) with selective plating, results in decreased scrap rates and reduced need for raw materials. The uniform processing of strip throughout each production stage decreases physical damage which results in fewer defects and reduced rework requirements. Manufacturers who implement production workflow integration of collaboration and sustainability are set to achieve long-term benefits which extend beyond environmental regulation compliance to create resilient supply chains that are both responsive and responsible.

With decades of experience in high-precision stamping and plating, Batten & Allen has built a reputation for delivering exceptional reel-to-reel component manufacturing to some of the world’s most demanding sectors. Their heritage as a specialist in this field is reflected not only in the quality of their components, but also in the way their processes have evolved and adapted to meet the ever-changing requirements of modern manufacturing.

The ability to offer stamping, electroplating and assembly entirely in-house sets Batten & Allen apart. The integrated system operates at peak performance through its ability to stop workflow fragmentation and quality inconsistencies while achieving maximum efficiency through advanced selective plating methods, pre-plated strip strategies, and state-of-the-art plating lines that produce millions of components daily.

The benefits of reel-to-reel production performed in-house become evident through reduced handling operations, accelerated production speeds and minimised material losses. Batten & Allen achieves these benefits at scale through their automation investments, process innovation and compliance capabilities which provide built-in reliability and traceability at every stage.

As markets demand increasingly complex, miniaturised and high-performance components, manufacturers need partners with both the expertise and infrastructure to support them. Batten & Allen’s deep knowledge of reel-to-reel technology, coupled with their commitment to sustainable and collaborative production practices, makes them a trusted and forward-thinking supplier in a global supply chain.

Your Reel-To-Reel Stamping Experts

We don’t just stamp – we design, plate, assemble and more, creating a simplified process to meet your demanding production needs.

Start a conversation