Tooling Design: How to Ensure Reliability from Prototype to Production

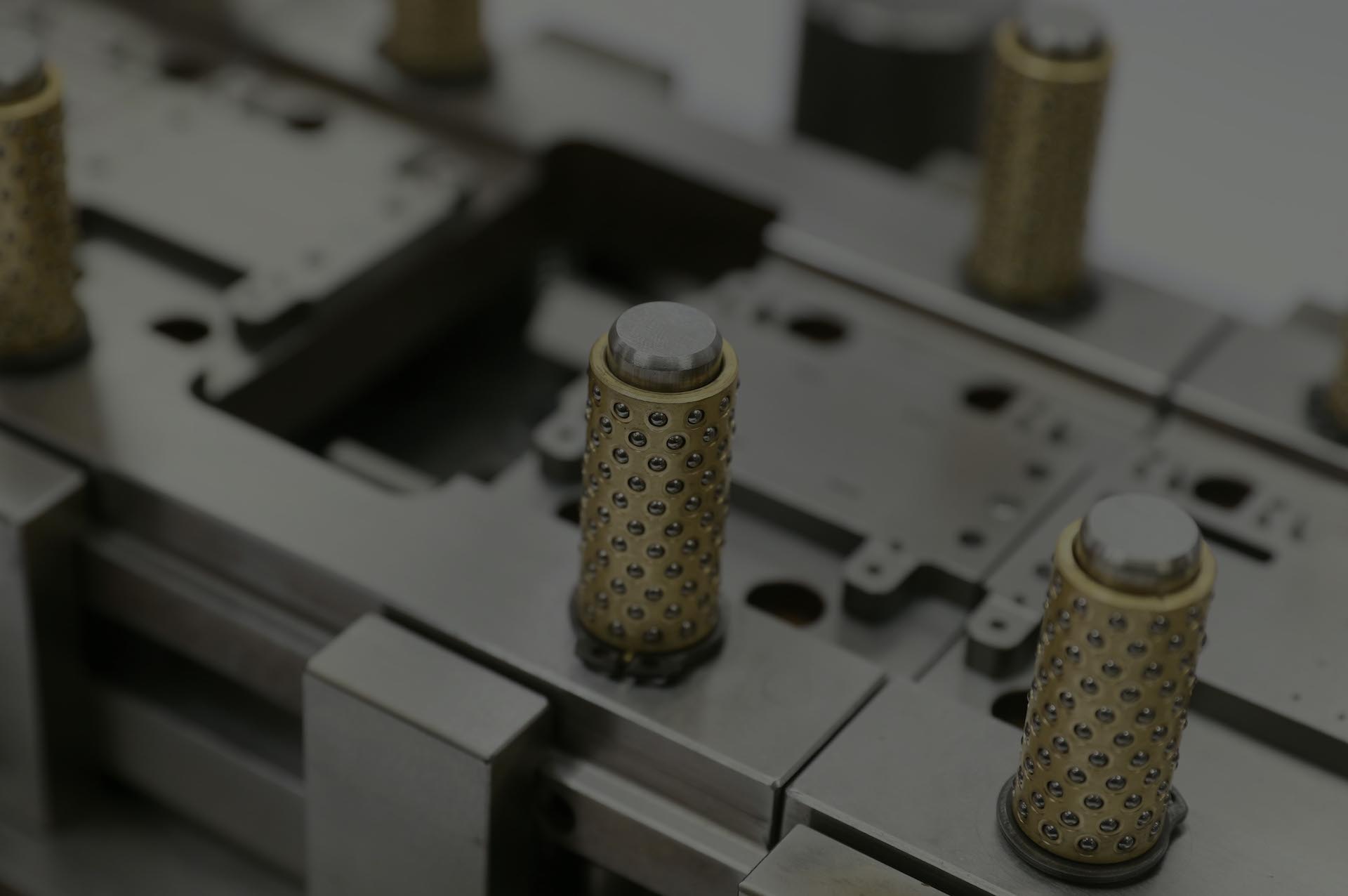

Built to last, our high accuracy, precision tooling is all designed and built in house. With a fully equipped toolroom we manufacture and design...

Brands are choosing us to partner with them to bring innovate products to market quickly and cost effectively.

Working on a Prototype and need expert input, why not get in touch and talk with our experts.

3 min read

Batten & Allen Sep 17, 2024 8:41:54 AM

Whether you’re launching a new product or scaling up production, understanding the financial implications is essential to maintain profitability. Cost estimation, however, can be complex, involving factors ranging from material expenses to labour costs.

Material costs can be the largest portion of the total project cost. This includes the cost of raw materials, components, and any specialised items required for your project.

It is important to consider both the unit cost of materials and any potential fluctuations in price due to market conditions or supplier negotiations. Labour costs encompass the wages paid to workers involved in the manufacturing process, from assembly line workers to quality control inspectors. Additionally, you must consider indirect labour fees, such as salaries of project managers, engineers, and other supporting staff.

Overheads

OverheadsOverhead costs include expenses that are not directly tied to the production of a specific product but are necessary to keep the manufacturing operation running. This can include utilities, equipment depreciation, facility maintenance, and administrative expenses.

Tooling and Equipment Costs

In many electronics manufacturing projects, specialised tooling and equipment are required. The cost of purchasing, maintaining, and potentially customising this equipment can be significant and should be carefully factored into the overall project cost.

Quality Assurance and Testing Costs

Ensuring the quality and reliability of electronic products is critical, which means that testing and quality assurance processes must be included in the cost estimation. These costs cover testing equipment, software, and the time required to conduct thorough inspections.

Logistics and Supply Chain Costs

Transportation, warehousing, and supply chain management are also significant cost factors, especially if your project involves multiple suppliers or if components are sourced internationally. Delays or disruptions in the supply chain can lead to increased costs, making it essential to include a buffer in your estimates.

Compliance and Regulatory Costs

Finally, compliance with industry standards and regulations can add to the overall project cost. This may involve certification fees, regulatory testing, and modifications to meet specific industry requirements.

With a clear understanding of the key cost components, the next step is to apply efficient methods for estimating these costs. Several approaches can be used depending on the project's complexity, timeline, and available data.

Analogous Estimation

This involves using the costs of similar past projects as a basis for estimating the current project's costs. This method is particularly useful in the early stages of a project when detailed information may not be available. By comparing the current project with past projects of similar scope and scale, you can quickly develop a rough estimate.

Parametric Estimation

This uses statistical models to estimate costs based on the relationship between different project variables. For instance, in electronics manufacturing, the cost per unit might be calculated by multiplying the number of units by a cost factor derived from historical data. This method is more accurate than analogous estimation and is ideal when you have access to reliable data and well-defined parameters.

Bottom-Up Estimation

Bottom-up estimation is a more detailed approach, where costs are estimated for each individual component or task and then aggregated to determine the total project cost. This method provides a higher degree of accuracy but can be time-consuming, making it best suited for projects where precision is critical and detailed information is available.

Three-Point Estimation

Three-point estimation considers three scenarios: optimistic, pessimistic, and most likely. By calculating the cost for each scenario and then averaging them, you can develop a more balanced estimate that accounts for potential uncertainties and risks. This method is particularly useful in complex projects where there is a high degree of uncertainty in cost factors.

Expert Judgement

Consulting with experts who have experience in similar projects can provide valuable insights and help refine your estimates. Expert judgement is often used in conjunction with other estimation methods to validate assumptions and identify potential cost drivers that may not have been considered.

One of the most common mistakes is failing to adequately account for contingencies. Unforeseen challenges, such as supply chain disruptions or unexpected material costs, can quickly inflate project expenses. Including a contingency buffer in your estimates can help mitigate these risks.

Another pitfall is overlooking indirect costs. Indirect costs, such as administrative expenses and facility maintenance, are often overlooked but can significantly impact the overall project cost. Ensuring all indirect costs are included in your estimate is crucial for accuracy.

Additionally, ignoring market volatility can lead to inaccurate estimates. Material and labour costs can fluctuate due to market conditions, such as changes in supply and demand or geopolitical events. Ignoring this can lead to significant cost overruns.

While historical data is a valuable resource, over-reliance on past projects can lead to inaccuracies if the current project differs significantly in scope or complexity. It is essential to adjust historical data to reflect the unique aspects of the current project.

Leveraging Tools for Accurate Estimation

Leveraging Tools for Accurate EstimationAccurate project cost estimation is a vital skill in electronics manufacturing, enabling better decision-making and financial planning. By understanding the key cost components, applying efficient estimation methods, and avoiding common pitfalls, you can develop more reliable cost estimates that will support your project's success.

For those looking to streamline this process, Batten and Allen’s Project Estimation Tool is available, offering a practical solution to quickly estimate costs. This tool simplifies the estimation process, helping you to consider all relevant factors and make informed decisions. Once you have your estimate, simply contact our team of experts who will be happy to discuss the finer points and detail the next steps.

Built to last, our high accuracy, precision tooling is all designed and built in house. With a fully equipped toolroom we manufacture and design...

As demand increases for smaller, more efficient devices, there has been a similar move towards higher precision-stamped components. these two right,...

Introduction Among the top priorities for anyone in the business of manufacturing and design engineering are longevity and reliability.