Crafting Excellence: Reliable Stamping Techniques for the Electronics Industry

Introduction In the fast-paced and ever-evolving electronics industry, the demand for precision and reliability in component manufacturing is a top...

Brands are choosing us to partner with them to bring innovate products to market quickly and cost effectively.

Working on a Prototype and need expert input, why not get in touch and talk with our experts.

3 min read

Batten & Allen Mar 4, 2024 4:05:38 PM

In the electronics industry, choosing the right material for your components and devices is not just a matter of preference but a critical decision that can significantly impact performance, durability, and cost.

As technology advances, the demand for more efficient, reliable, and miniaturised components grows, making the material selection process even more important.

This comprehensive guide aims to open up the key factors when selecting materials for electronic applications, ensuring you get the right material for the right job.

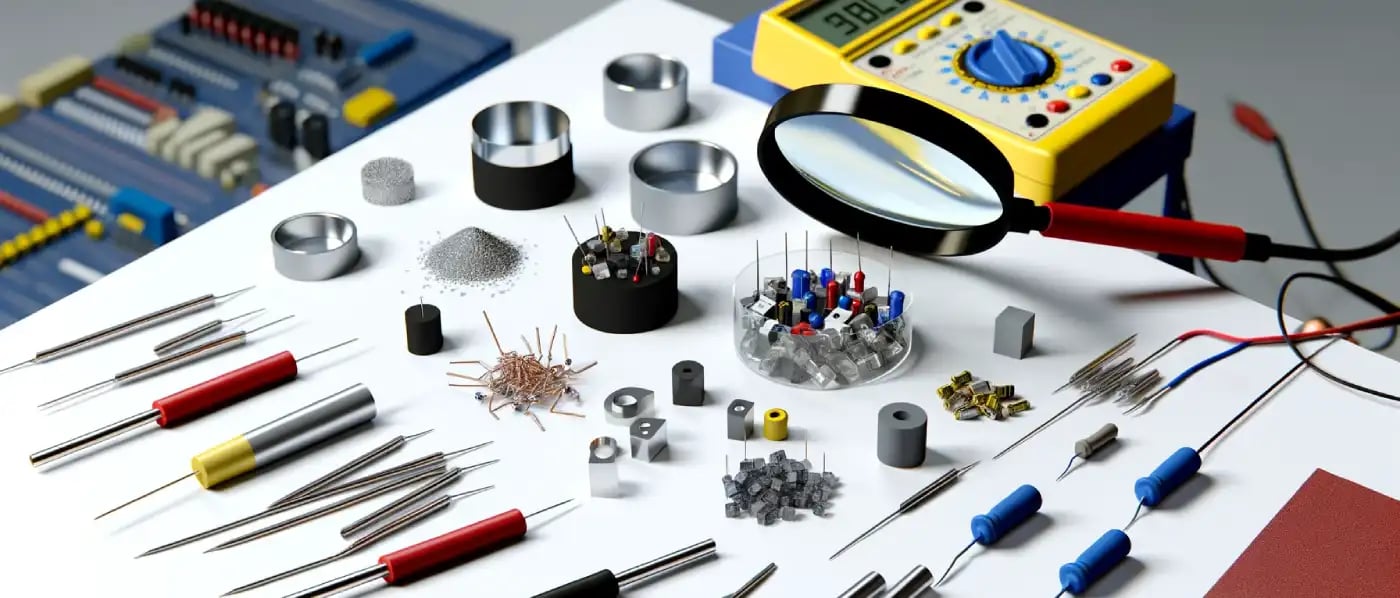

Electrical conductivity is probably the most critical property to consider in the electronics industry. Materials with high conductivity, such as copper and silver, are commonly used in wiring and components where efficient electrical transmission is crucial. However, the choice of conductor material can also depend on other factors, such as cost, weight, and corrosion resistance.

The ability of a material to deal with heat is another consideration. Components in electronic devices can generate significant amounts of heat, which, if not properly dissipated, can lead to performance degradation or even failure.

Materials with high thermal conductivity, like aluminium and copper, are often used for heat sinks and other cooling mechanisms.

The strength, flexibility, and durability of materials are essential, especially in devices subjected to mechanical stress or harsh environments. Polymers, ceramics, and composites are selected based on their mechanical properties to ensure the long life and reliability.

Electronic components can be exposed to various chemicals, including solvents and corrosive substances. Materials resistant to such chemicals are crucial for ensuring the reliability of electronic devices, particularly in industrial or outdoor applications.

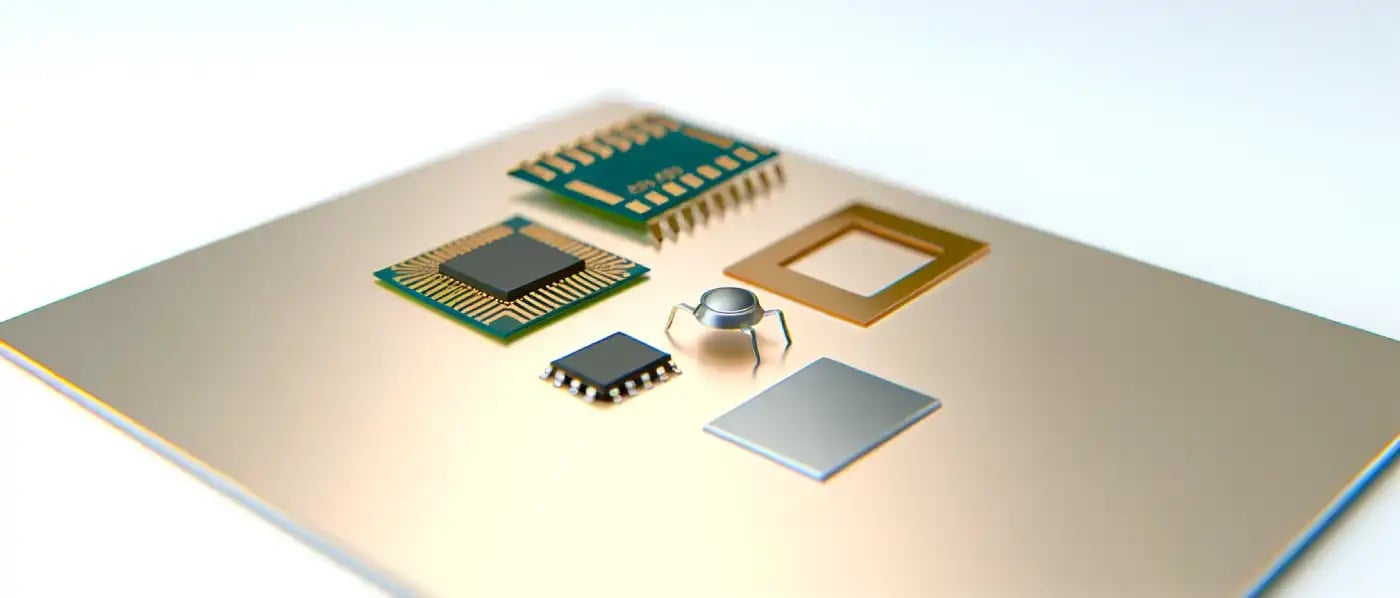

Printed Circuit Boards (PCBs) are the backbone of most electronic devices. The choice of material for PCBs, typically fiberglass composites like FR4, impacts the board's durability, performance, and cost.

Advanced applications could require materials with higher thermal conductivity or lower dielectric constants, such as ceramic-filled composites or PTFE-based materials.

Silicon has long been the material for semiconductor devices due to its excellent semiconducting properties. However, new applications requiring higher speed, efficiency, or operation at extreme temperatures have led to the exploration of alternative materials like gallium arsenide (GaAs) and silicon carbide (SiC).

The materials used for encapsulating and packaging electronic components play a big part in protecting against physical damage, moisture, and chemical exposure.

Epoxy resins, silicones, and ceramics are commonly used for their protective properties, thermal management capabilities, and electrical insulation.

The choice of materials for bonding components is critical for ensuring electrical conductivity and mechanical strength. Lead-free solders and conductive adhesives are becoming more common, driven by environmental regulations and the need for lower processing temperatures.

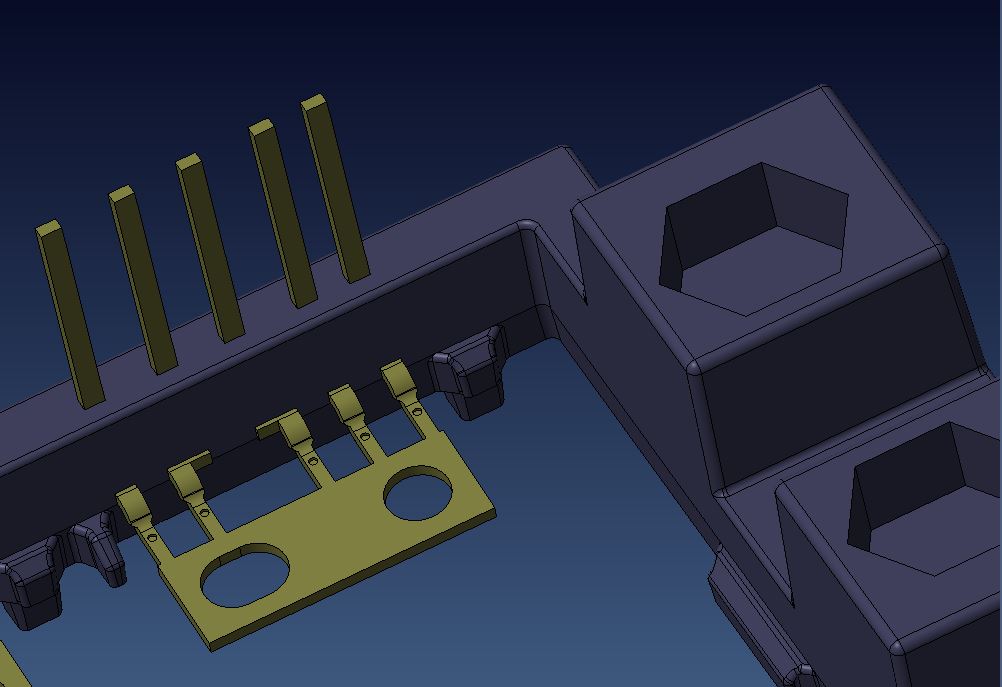

The electronics industry is continually seeking new materials to overcome current limitations and enable new technologies.

Innovations in nanomaterials, such as graphene and carbon nanotubes, offer exceptional electrical, thermal, and mechanical properties in incredibly lightweight and flexible forms. These materials are leading the way in advancements in flexible electronics, wearables, and next-generation computing technologies.

Sustainability is becoming more of a priority in the electronics industry. The selection of materials now often includes considerations of environmental impact, recyclability, and compliance with international standards and regulations.

Materials that are less harmful to the environment and easier to recycle are preferred, aligning with global efforts towards greener electronic products.

Given the complexity of material selection and the specific requirements of each application, consulting with experts in the field can be invaluable.

Companies like Batten & Allen, with decades of experience in precision engineering and manufacturing for the electronics industry, can help in providing insights and guidance on choosing the right materials for your specific needs. Their expertise can help ensure your products not only meet but exceed industry standards, combining performance, reliability, and sustainability.

Choosing the right material for electronic components and devices is a process that requires a deep understanding of material properties, application requirements, and emerging trends.

By considering electrical and thermal conductivity, mechanical strength, chemical resistance, and environmental impact, you can make informed decisions to enhance the performance and sustainability of your products.

Engaging with industry experts can further refine your material selection process, ensuring your electronics meet the evolving demands of technology and consumers alike.

Get personalised guidance for your electronics project from our experts. Ensure your components meet the highest standards of performance and durability.

Reach Out Now

Introduction In the fast-paced and ever-evolving electronics industry, the demand for precision and reliability in component manufacturing is a top...

The ability to estimate project costs is a fundamental part of the manufacturing process. Whether you're developing cutting-edge consumer electronics...

In the intricate world of electronics, material selection plays a pivotal role in determining the performance, reliability, and longevity of...